Custom solutions for demanding applications

Sound attenuation

Our Address

Tridelta Siperm GmbH

Ostkirchstr. 177

44287 Dortmund, Germany

Sound attenuation in pneumatic applications with porous sintered materials

Classification and technical significance of sound attenuation

Acoustic emissions in pneumatic systems mainly occur where gases escape from the system unchecked. Typical points of origin are vents of valves, cylinders, compressed air motors and control and regulation components. The combination of high flow velocity and turbulent flow components leads to characteristic flow noises with sometimes high sound pressure levels.

In industrial applications, sound attenuation should therefore not be considered solely in terms of occupational health and safety. In addition to reducing noise pollution for operating personnel, the type of ventilation also influences the stability and cleanliness of system operation. Uncontrolled exhaust air flows can stir up dust, introduce particles or lead to undesirable pressure fluctuations.

Modern pneumatic systems therefore place increased demands on silencers. In addition to the acoustic effect, these components must control the venting process in terms of flow without changing the process sequence or impairing valve and actuator functions.

Porous sintered materials have proven themselves for this task, as they combine sound absorption and flow control in one functional component.

Technical objective of sound attenuation

The technical objective of sound attenuation in pneumatic applications can be divided into three central aspects:

-

Reduction of noise emissions when gases escape

-

Controlled ventilation without harmful turbulence

-

Process-neutral operation without unacceptable backflow effects

In contrast to simple throttle or deflection solutions, silencers made of porous materials are designed to reduce the volume flow evenly. This calms the ventilation without changing the function of valves, cylinders or motors.

Another technical aspect is the durability of the damping effect. In many applications, venting processes take place cyclically and at high frequency. The sound attenuation must therefore remain stable regardless of the number of cycles, operating pressure and changing load conditions.

Basic technical principle of sound attenuation

Sound attenuation with porous sintered materials is based on the targeted influencing of the outflowing gas flow. The aim is to reduce the turbulent flow components that arise during venting and to minimize the generation of sound at the source. No moving parts or additional absorption media are used, but only the defined internal structure of the porous material.

Porous sintered materials consist of interconnected pore channels whose geometry and distribution are determined by the sintering process. This structure enables a uniform flow over the entire surface of the component.

Uniform flow guidance in the pore structure

When the exhaust air enters the porous silencer, the volume flow is distributed over a large number of fine channels. This significantly reduces the local flow velocity. Instead of a directed jet with high outlet energy, a diffuse, planar flow is created.

This uniform flow control has the following effects:

-

Reduction of the flow velocity

-

Reduction of turbulent flow components

-

Uniform pressure reduction across the entire cross-section

The venting process is therefore smoother and more reproducible, regardless of short-term pressure fluctuations in the system.

Reduction of sound energy in the porous body

Within the pore channels, friction occurs between the flowing gas and the inner surface of the sintered material. In addition, the gas flow is deflected and split several times. These effects lead to a conversion of sound energy into heat.

The sound attenuation is broadband and is not limited to individual frequencies. This means that the damping effect remains stable even under changing operating conditions, for example with varying switching frequencies or pressure levels.

Process-neutral pressure reduction

A key criterion for use in pneumatic applications is process-neutral operation. Silencers made of porous sintered materials are designed in such a way that the necessary volume flow is dissipated without generating impermissible back pressures.

When properly designed, they remain:

-

the switching behavior of valves

-

the movement sequences of cylinders

-

the function of pneumatic motors

unchanged. The sound attenuation has a supplementary effect and does not interfere with the process logic of the system.

Central applications of sound attenuation

Silencers made of porous sintered materials are used in pneumatic systems wherever gases need to be discharged into the environment in a controlled and low-noise manner. The application is not limited to individual components, but often affects entire system areas with numerous venting points.

They are preferably used on components with high flow velocities and frequent switching cycles. In addition to noise reduction, functional aspects such as process stability, cleanliness and component protection play a central role.

Valves and control blocks

Pneumatic valves briefly generate high volume flows when venting the switching chambers. Without suitable silencing, pronounced flow noises occur. Silencers made of porous sintered materials are mounted directly on the vent openings and take over the controlled discharge of the exhaust air.

The even pressure reduction not only reduces the noise level, but also ensures reproducible switching operations. Uncontrolled pressure peaks and turbulence at the outlet are avoided, which has a positive effect on the functional reliability of the valves.

Pneumatic cylinders and actuators

With cylinders, noise emissions occur in particular when the piston chambers are vented quickly. This is particularly relevant at high cycle rates and short strokes. Porous silencers discharge the exhaust air evenly and prevent the formation of localized exhaust jets.

The result is a smoother movement of the actuator without the stroke speed being specifically throttled. This maintains the dynamics of the application while significantly reducing noise.

Air motors and pneumatic drives

Air motors continuously emit exhaust air during operation. Without silencing, this results in continuous noise emissions, which can have a particularly disruptive effect in production environments. Silencers made of porous sintered materials enable continuous, uniform ventilation.

In addition to the acoustic effect, contamination of the environment is also reduced, as particles and oil mist do not escape unchecked.

Measuring devices and sensor-related applications

Porous components are often used in measurement and control technology to protect sensitive components from external influences. In applications with exhaust air or reference gases, porous silencers also have a noise-reducing function.

The calmed flow improves the stability of the measuring conditions and protects sensors from mechanical stress and contamination.

Technical advantages in system operation

The use of porous silencers not only has an effect on noise development, but also influences several technical aspects of system operation. The controlled venting creates effects that go beyond pure noise reduction and contribute to the stabilization of pneumatic processes.

Smooth venting process

The uniform distribution of the volume flow within the porous structure significantly calms the venting process. High velocity point jets are avoided. This leads to uniform pressure relief at the venting point.

The smooth venting process is particularly advantageous for frequent switching cycles and fast movement sequences, as short-term pressure peaks are reduced.

Reduced wear of adjacent components

Unrestrained exhaust air flows can mechanically stress adjacent components or whirl up particles that penetrate moving components. Controlled exhaust air routing significantly reduces this load.

The lower mechanical stresses have a positive effect:

-

Valve seats and seals

-

Cylinder guides

-

Adjacent control and sensor components

and contribute to longer service lives.

More stable processes

Silencing with porous sintered materials contributes to process stability, as the pressure reduction is reproducible. Fluctuations in venting behaviour are reduced, which is particularly relevant for synchronized movements of several actuators.

In complex systems with many venting points, this prevents unwanted interactions between individual components.

Reduced pollution of the environment

Due to the extensive ventilation, dust, particles or oil mist are less likely to enter the environment. This is particularly important in sensitive production areas where cleanliness and defined ambient conditions are required.

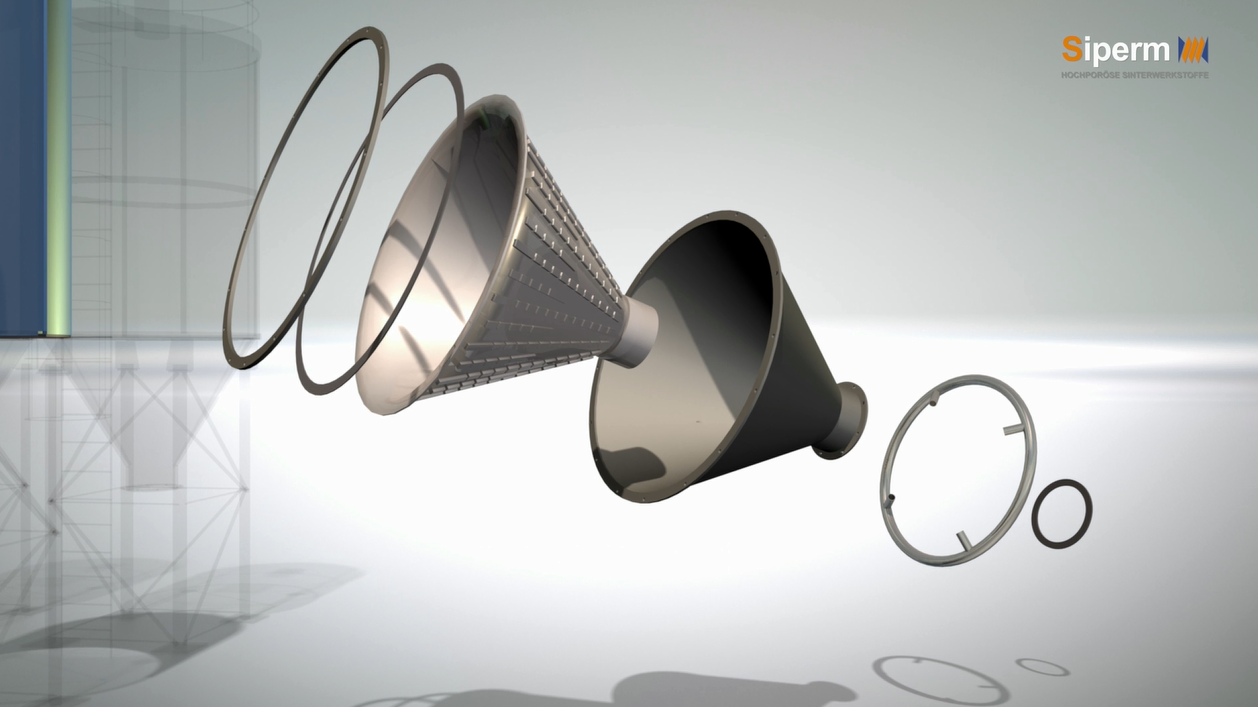

Designs and integration of silencers

Silencers made of porous sintered materials are available in various designs to adapt to the respective installation situations and functional requirements of pneumatic systems. The decisive factor here is the combination of sufficient flow area, compact design and simple integration into existing components.

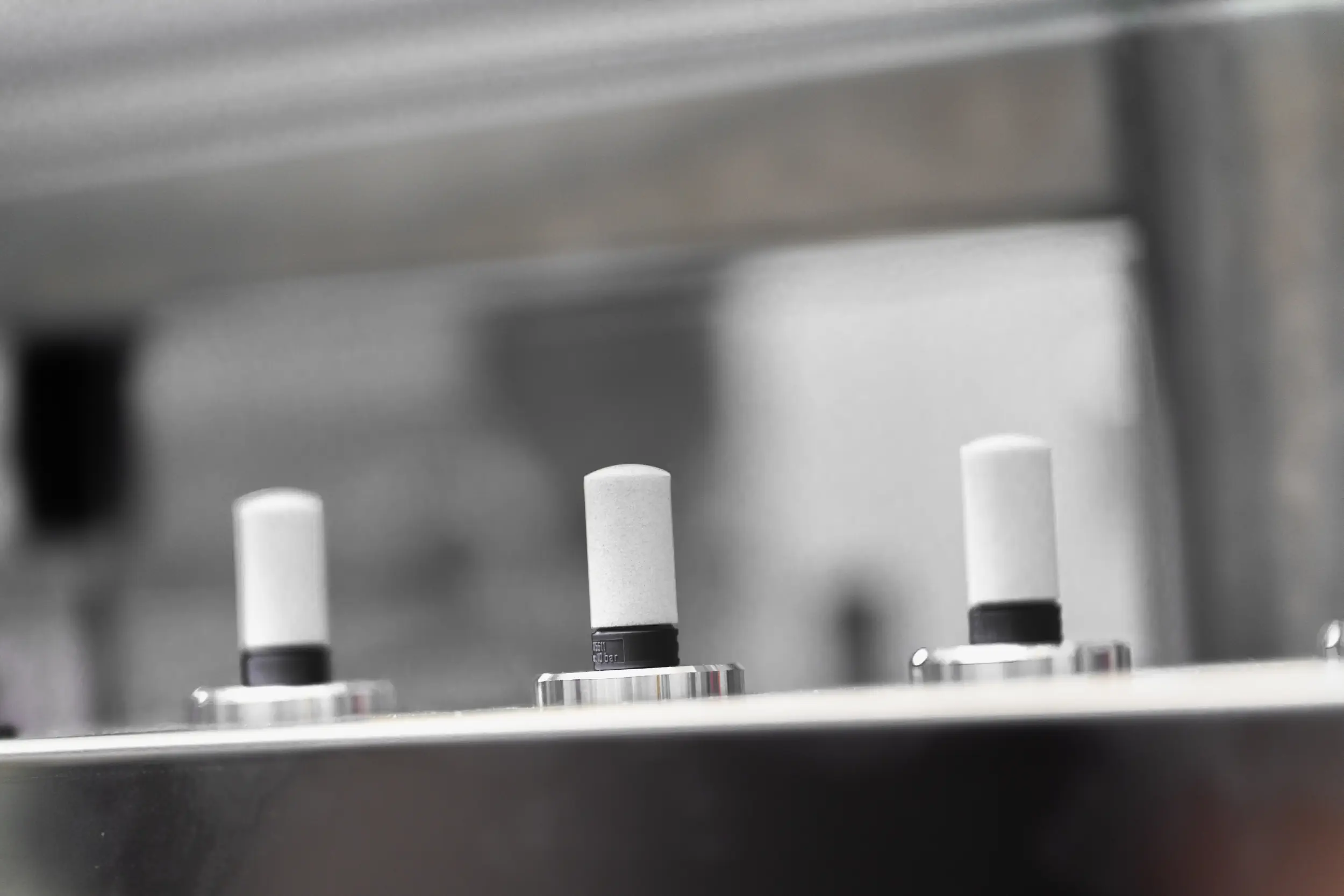

Threaded silencer

Silencers with an integrated connection thread are a common design. They are screwed directly into the vent openings of valves, control blocks or cylinders. This design enables simple retrofitting without any design changes to the system.

The porous sintered body absorbs noise, while the solid connection piece ensures mechanical stability and tightness. Depending on the application, different thread shapes and sizes can be realized.

Silencers as molded parts or inserts

In applications with limited installation space or special geometric requirements, porous silencers are designed as customized moulded parts. These can be integrated directly into housings, covers or ventilation ducts.

Thanks to the form-fit integration, flow paths can be specifically designed without having to provide additional attachments. This solution is often used in series applications or for compact assemblies.

Integration in assemblies and devices

Porous silencers can also be part of larger assemblies, for example in pneumatic drives, measuring devices or control housings. In such cases, the porous material performs several functions simultaneously, such as sound attenuation and flow stabilization.

Integration into existing assemblies reduces the number of individual components and simplifies installation and maintenance.

Materials for sound attenuation (application-related)

The selection of a suitable material for silencers made of porous sintered materials depends on the respective operating conditions of the application. The medium, temperature, chemical load and mechanical requirements are decisive factors. Metallic and polymeric materials are available for sound attenuation, each of which has specific properties.

Porous polyethylene (SIPERM® HP)

Porous polyethylene is used where chemical resistance, low weight and flexible geometries are paramount. The material is particularly suitable for applications with low operating temperatures and aggressive media.

Relevant properties:

-

High chemical resistance

-

Low weight

-

Suitable for complex geometries

-

Use at moderate temperatures

Porous polyethylene silencers are often used in compact assemblies, measuring devices or applications with special requirements for media compatibility.

Porous stainless steel (SIPERM® R)

Porous stainless steel is used when there are increased requirements for temperature resistance, mechanical strength and chemical stability. Typical applications are found in industrial pneumatic systems with demanding environmental conditions.

Characteristic properties:

-

Use at elevated temperatures

-

High mechanical stability even with pulsating loads

-

Resistance to many technical gases

-

Suitable for continuous, cyclical venting processes

Due to its robust properties, porous stainless steel is often used in valves, compressed air motors and safety-relevant applications.

Porous bronze (SIPERM® B)

Porous bronze is characterized by a uniform pore structure and good flow properties. The material is particularly suitable for applications with oily exhaust air or technical gases.

Typical features:

-

Good resistance to oils and lubricants

-

Low pressure losses with defined sound attenuation

-

Proven use in standard pneumatic applications

Porous bronze is often used in classic pneumatic systems where reliable sound absorption at moderate temperatures is required.

Operation, maintenance and service life

Silencers made of porous sintered materials are designed for long-term use in pneumatic systems. The absence of moving parts and additional absorption media results in robust components with low maintenance requirements. Nevertheless, operational conditions must be taken into account to ensure consistent function.

Operation under industrial conditions

During operation, exhaust air continuously flows through porous silencers. Depending on the application, particles, oil mist or condensate can be carried along. The porous structure is designed so that the flow remains stable even under changing load conditions.

Proper design in terms of porosity and component geometry is essential for reliable operation. A pore structure that is too fine can lead to increased flow resistance with heavily loaded exhaust air, while pores that are too coarse reduce the damping effect.

Contamination and cleanability

In applications with a high particle or oil load, deposits may form within the pores in the long term. The degree of contamination depends heavily on the medium and the operating conditions.

Different cleaning methods are possible depending on the material and application. The choice of cleaning method must be based on the chemical resistance of the respective material and must not impair the porous structure.

Service life and functional reliability

When used properly, porous silencers achieve a long service life. The silencing effect remains stable over long periods of time, as no materials can age or become loose.

Replacement is generally only necessary if the flow is permanently restricted by deposits or if the operating conditions of the system change significantly.

Design, customized solutions and technical summary

Design of silencers for pneumatic applications

The design of silencers made of porous sintered materials is always application-specific. The required volume flow, the pressure level, the permissible pressure difference and the properties of the medium to be discharged are decisive. The aim is to achieve sufficient sound attenuation without inadmissibly influencing the venting process.

A careful interpretation takes this into account:

-

Operating pressure and venting volume

-

Switching frequency and number of cycles

-

Medium (air, technical gases, oily exhaust air)

-

Ambient conditions and installation situation

Porosity, wall thickness and component geometry are determined on this basis.

Customized solutions

Standardized silencers cover many applications. In more complex cases, customer-specific solutions are required, for example for confined installation spaces, special connection geometries or integrated assemblies.

Porous sintered materials allow a high degree of design freedom. Silencers can be designed as separate components, as integrated inserts or as part of complex assemblies. They can be adapted without changing the basic operating principle.

Technical summary

Sound attenuation with porous sintered materials is a functional solution for pneumatic systems in which acoustic and fluidic requirements are combined. The controlled exhaust air flow reduces noise emissions without changing the process sequence.

The most important features at a glance:

-

Wide, frequency-independent sound attenuation

-

Uniform pressure reduction without backflow effects

-

Robust design without moving parts

-

Application-related material selection

-

Long service life with low maintenance requirements

Contact

We are happy to advise you – simply contact us by phone, via email or by using our contact form.

Service

Tridelta Siperm GmbH

Ostkirchstr. 177

44287 Dortmund, Germany