Custom solutions for demanding applications

Fluidization with antistatic PE

Our Address

Tridelta Siperm GmbH

Ostkirchstr. 177

44287 Dortmund, Germany

Capillary transport and storage with porous sintered materials

Classification and technical significance

Capillary transport and the storage of liquids are functional tasks in numerous industrial applications. They are used wherever liquids have to be picked up, distributed, stored or dispensed in a controlled manner over a longer period of time without active conveying systems. Typical requirements are uniform dosing, a low-maintenance design and reproducible function over the entire service life.

Porous sintered materials are suitable for these tasks as they have a network of interconnected pore channels. Capillary forces act in these pores, which can absorb liquids and retain them in the material. The release is passive and depends on the respective application, for example through contact, movement or consumption at a defined point.

SIPERM® sintered materials are used in this context as passive functional components. They do not generate any pressure and do not actively transport any liquids, but only use physical capillary effects. The material, porosity and surface properties are designed to suit the application in order to achieve the desired storage and transport function.

Functional use of porous sintered materials

Porous sintered materials take on two central tasks in capillary transport:

-

Absorption and storage of liquids within the pore structure

-

Targeted release of the stored liquid to a defined contact point

These functions can be combined in one component. This eliminates the need for additional components such as pumps, valves or dosing systems. The components operate silently, require little maintenance and are independent of an external energy supply.

SIPERM® materials are used for capillary transport and storage, especially where constant quantities of liquid have to be supplied over long periods of time or where compact integration into assemblies is required.

Capillary action and fluid transport in porous structures

Capillary transport in porous sintered materials is based on physical capillary forces that act in the fine, interconnected pore channels. These forces make it possible to draw liquids into the material without external energy input, hold them there and release them again as required. Pore size, pore distribution and the surface properties of the material are decisive factors here.

In porous structures, capillary action occurs when the interaction between the liquid and the pore surface is stronger than gravity or other opposing forces. The finer and more uniform the pores, the more stable and reproducible the liquid transport.

Absorption of liquids

A liquid is absorbed by wetting the inner pore surfaces. As soon as a suitable liquid comes into contact with the porous component, it is drawn into the pore channels. This process depends on:

-

the surface tension of the liquid

-

the contact angle between the liquid and the pore surface

-

the pore geometry and distribution

Porous SIPERM® sintered materials are designed in such a way that absorption is targeted and uniform, without local overfilling or uncontrolled leakage.

Storage within the pore structure

After absorption, the liquid is stored within the pore structure. The capillary forces retain the liquid in the material and prevent it from leaking out on its own. The amount of liquid that can be stored is essentially determined by the pore volume.

This storage function is stable over long periods of time as long as no external influences such as temperature changes, mechanical loads or liquid consumption occur at the dispensing point.

Release of the stored liquid

The release takes place passively when a demand arises at a defined point, for example through contact with a component, through movement or through continuous consumption. The fluid is replenished from the pore system until a state of equilibrium is reached.

SIPERM® components therefore enable a continuous, even supply of liquid without active dosing mechanisms.

Surface properties of polyethylene

The surface properties of the material play a central role in capillary transport and the storage of liquids. In the case of porous polyethylene, they determine which liquids can be absorbed and how stable the capillary transport is. SIPERM® polyethylene has clearly defined, application-relevant properties.

Basic hydrophobic property of polyethylene

Due to its chemical structure, polyethylene is a non-polar material. The surface does not contain any polar functional groups, which means that water and aqueous media only wet the surface poorly. Untreated porous polyethylene is therefore hydrophobic.

This means for capillary transport:

-

Aqueous liquids do not penetrate the pores, or only to a very limited extent

-

Capillary action for water does not take place without additional measures

-

liquid absorption is limited to suitable, non-polar media

Untreated porous polyethylene is therefore not suitable for applications where moisture or water-based liquids are to be stored or transported.

Hydrophilic adjustment of porous polyethylene

Porous polyethylene can be made hydrophilic through targeted surface treatment. The uppermost molecular layers of the pore surface are changed in such a way that polar properties are created. The pore structure itself remains unchanged.

The hydrophilic setting has the following effects:

-

Improved wetting of the pore surfaces by water

-

Reduction of the contact angle

-

Enabling the capillary transport of aqueous media

-

Absorption and storage of moisture or water-based liquids

Hydrophilic SIPERM® polyethylene is used when liquids need to be absorbed, stored and released in a controlled manner.

Lipophilic properties of polyethylene

Regardless of a hydrophilic setting, polyethylene has a naturally high affinity for lipophilic media. Oils, greases and many lubricants wet the surface very well and are reliably absorbed into the pore structure.

This means for porous polyethylene:

-

Stable capillary transport for oils and lubricants

-

High storage capacity for lipophilic liquids

-

Uniform release via the pore structure

These lipophilic properties are intrinsic and do not require any additional surface treatment. SIPERM® polyethylene is therefore often used as a lubricant depot or fluid reservoir for oil-based media.

Media-related selection of surface properties

The choice between hydrophobic, hydrophilic or lipophilic porous polyethylene always depends on the medium. The decisive factor is the liquid that is to be stored or transported. By specifically adjusting the surface properties, the same base material can be used for different applications.

Central applications for capillary transport and storage

Capillary transport and the storage of liquids with porous sintered materials are used in applications in which liquids have to be supplied passively, evenly and over defined periods of time. The porous material assumes the function of an integrated depot and transport element at the same time. SIPERM® components are designed for specific applications and integrated into existing assemblies.

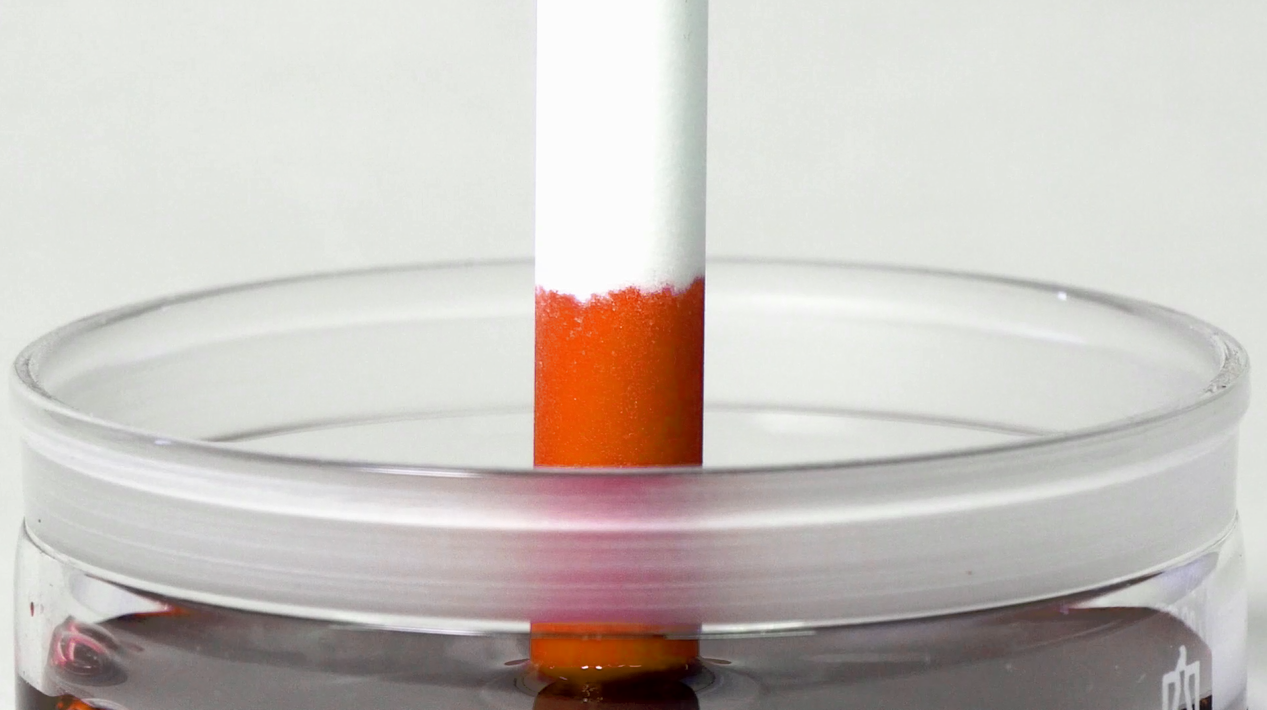

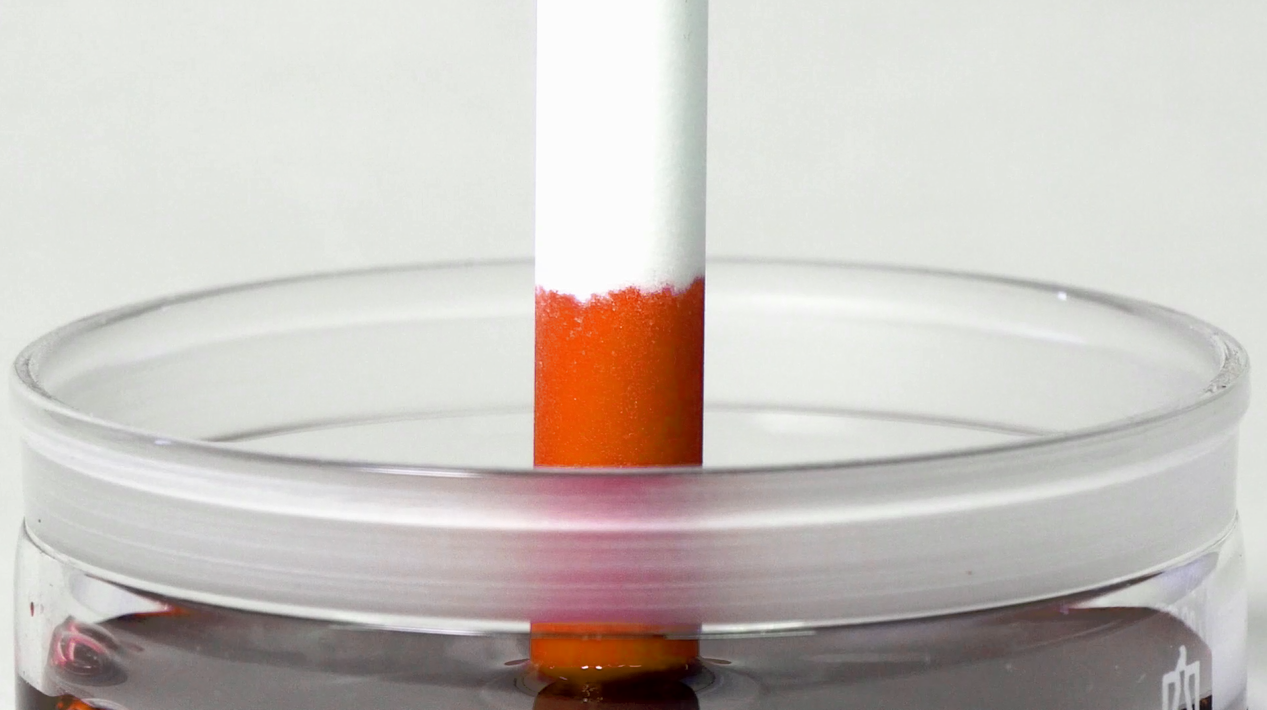

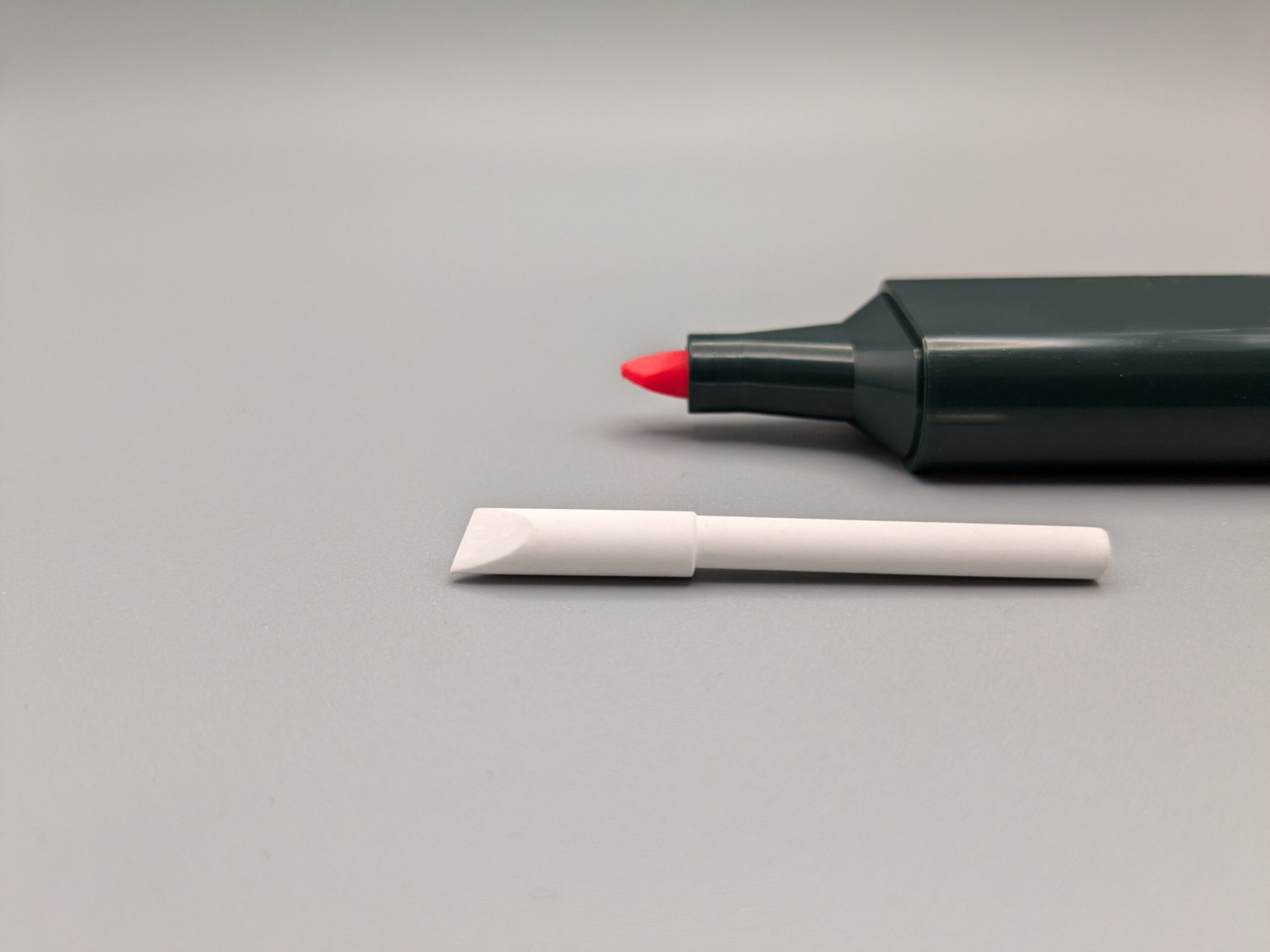

Writing and marking systems

In writing tips, markers and technical drawing systems, porous sintered materials serve as a storage and transport medium for inks. The liquid is stored in the pore volume and continuously released to the writing tip via capillary forces.

The uniform dispensing ensures reproducible line images and prevents uncontrolled leakage or drying out. Depending on the ink type, hydrophilic or lipophilic material variants are used.

Integration in assemblies

In many applications, capillary transport and storage functions are integrated directly into assemblies. Porous SIPERM® components perform several functions simultaneously and replace separate storage or dosing components. This enables compact, robust and low-maintenance solutions.

Lubricant storage and permanent lubrication

Porous SIPERM® sintered materials are often used as lubricant depots when moving components need to be lubricated permanently and with low maintenance. Oils or lubricants are stored in the material and released to the friction point as required via capillary forces.

Typical applications can be found in small electric motors, bearings, guides or precision mechanical assemblies. The lubricant is dispensed evenly and without active metering systems.

Scent and active ingredient storage

Porous sintered materials are used as a carrier material for the storage and controlled release of active ingredients or fragrances. The liquid is bound in the pore system and released over longer periods of time.

The choice of material, porosity and surface properties depends on the respective active ingredient and the desired release properties.

Textile and thread treatment

In textile applications, porous sintered materials are used to release oils or other additives in a controlled manner onto fast-moving threads. The material stores a defined quantity of liquid and releases it evenly during operation.

This allows constant process conditions to be achieved, for example to reduce friction or improve thread guidance.

Materials for capillary transport and storage

For capillary transport and the storage of liquids, porous sintered materials are selected so that the pore structure, surface properties and chemical resistance match the respective liquid and application. The material not only determines the storage capacity, but also the stability of the capillary effect over the duration of use.

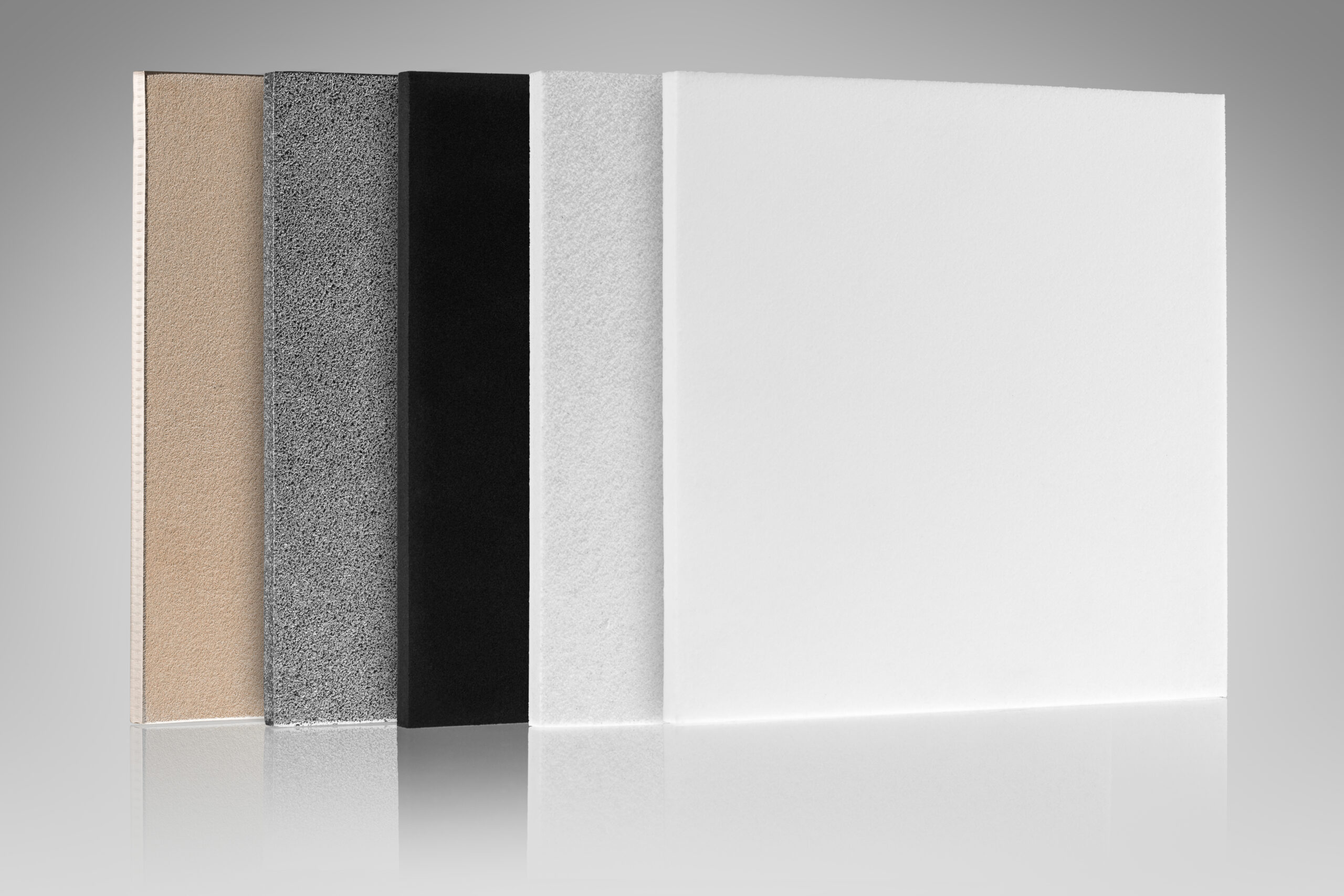

Porous polyethylene – SIPERM® HP

Porous polyethylene is the key material for capillary storage and transportation applications. Its mechanical stability, chemical resistance and the ability to adjust the surface properties make it highly versatile.

Application-relevant properties:

-

Defined pore structure for reproducible capillary transport

-

hydrophobic basic property for lipophilic media

-

Hydrophilic setting possible for aqueous liquids

-

High resistance to many oils, greases and active ingredients

-

Low weight and good integration capability

SIPERM® HP is used when liquids need to be stored and dispensed in a controlled manner over long periods of time without active dosing mechanisms.

Metallic porous sintered materials SIPERM®-R and SIPERM®-B

Metallic porous sintered materials can also be used in special applications, for example when higher temperatures, mechanical loads or special environmental conditions are present. In the area of capillary transport, the focus is not on filtration or structural functions, but on the storage and release function for suitable media.

The use of metallic materials is application-specific and takes into account the respective fluid and operating conditions.

Material selection in the application context

The selection of a suitable material is always media- and function-related. The decisive factors are

-

Type of liquid (aqueous, oily, containing active ingredient)

-

Desired storage and delivery quantity

-

Ambient conditions such as temperature and movement

-

Installation situation and mechanical requirements

Material, porosity and surface condition are considered together to ensure a stable capillary effect and reliable function over the entire service life.

Application-related design

The design of capillary transport and storage elements is always application-specific. The decisive factors are

-

Type and properties of the liquid

-

Desired storage quantity

-

Dispensing behavior and contact conditions

-

Porosity and geometry of the component

-

Surface properties of the material

Porous SIPERM® sintered materials are designed to provide reliable capillary transport and storage without the need for additional components or active systems.

Technical summary

Capillary transport and the storage of liquids with porous sintered materials are based on physical capillary forces within a defined pore structure. Liquids are passively absorbed, stored in the material and released again in a controlled manner as required. The function takes place without active conveying systems, pressure generation or moving components.

Porous SIPERM® sintered materials are designed for these applications. The decisive factors are porosity, geometry and the surface properties of the material. Porous polyethylene in particular is suitable for a wide range of liquids due to its chemical resistance and the possibility of hydrophilic adjustment. Untreated polyethylene is hydrophobic and lipophilic and therefore predestined for oil-based media and lubricants. Through targeted surface treatment, it can be made hydrophilic in order to absorb and store aqueous liquids.

Typical applications can be found in writing and marking systems, in lubricant storage and permanent lubrication, in the storage of fragrances and active ingredients as well as in textile technology processes. In all cases, porous SIPERM® components assume the function of an integrated depot with reproducible release over long periods of use.

Capillary transport and storage with porous sintered materials thus represent a robust, low-maintenance and constructively integrable solution for industrial applications in which liquids have to be guided in a targeted and passive manner.

Our materials

Contact

We are happy to advise you – simply contact us by phone, via email or by using our contact form.

Service

Tridelta Siperm GmbH

Ostkirchstr. 177

44287 Dortmund, Germany