Custom solutions for demanding applications

Bulk material handling

Our Address

Tridelta Siperm GmbH

Ostkirchstr. 177

44287 Dortmund, Germany

Bulk material handling with porous SIPERM® materials

The storage, conveying and discharge of fine-grained, powdery bulk materials with grain diameters <0.2 mm places high demands on system technology and material selection. These materials have poor flow properties, form bridges and shafts and thus lead to process instability and additional costs.

SIPERM® aeration elements made of porous stainless steel, bronze or polyethylene materials ensure reliable, low-maintenance and economically advantageous solutions in silo technology – suitable for both new systems and retrofitting.

For bulk materials such as cement, pigments, carbon black, pesticides or fine plastic powder, all SIPERM® materials. Both Siperm R (stainless steel /1.4404) and Siperm HP (PE with food conformity declaration) are suitable for bulk materials in the food sector, such as flour.

Ventilation, deaeration, fluidization and compression

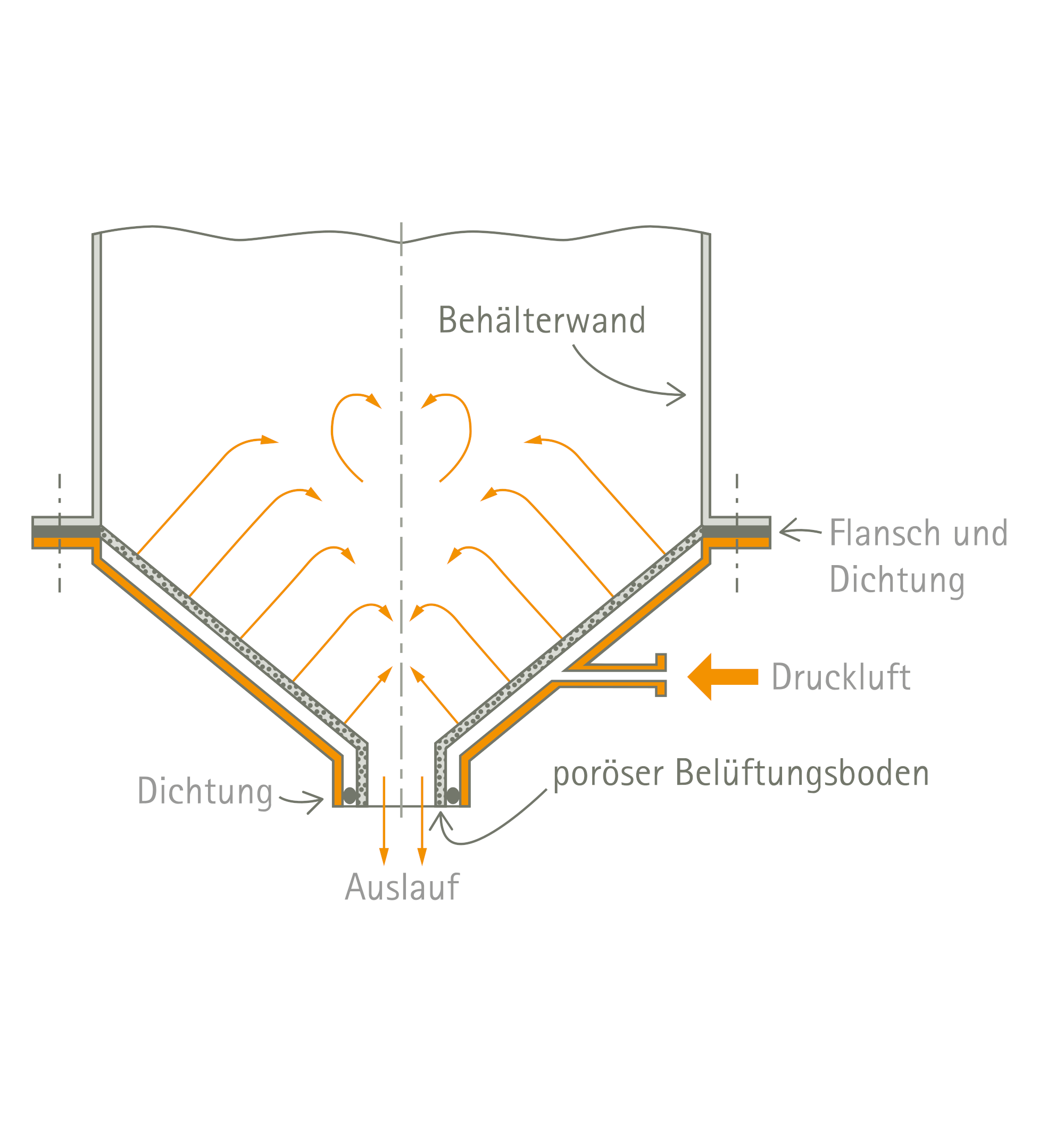

SIPERM® materials enable uniform gas distribution in the bulk material bed and thus influence its flow, deaeration and compaction properties. The porous structure has a two-dimensional effect and prevents localized overflow or material congestion. Depending on the design, the components serve as aeration cushions, spots, funnels, fluidization bottoms or suction pipes. They support the discharge behaviour, stabilize the material movement, reduce trapped air and enable controlled homogenization, drying or cooling processes. The function is always based on the defined flow over the entire component surface.

In industrial plants, fine-grained or unevenly flowing bulk materials often cause difficulties during storage, conveying and discharge. Materials compact, form bridges or remain in the discharge area. Porous SIPERM® materials allow the bulk material behavior to be influenced in a controlled manner by introducing process gases into the material or discharging them from it in a defined manner. The uniform pore structure distributes the gas flow over the entire surface and prevents local overloading, which can occur with point-shaped nozzles.

The components are made of stainless steel, bronze or polyethylene and are integrated into silos and conveyor systems as aeration floors, cushions, spots, inserts or suction pipes. The pores ensure that gas flows through the material in a controlled manner. This improves the flow behaviour, enables homogenization, supports drying or cooling and allows the safe deaeration or compaction of fine powders. The mode of operation is comparable in all applications: The gas flow introduced through the porous structure changes the internal forces of the bulk material and creates reproducible process conditions.

Advantages of our ventilation elements at a glance:

- Specifically adjustable pore size

- Uniform air flow across the entire cross-section

- constructively simple solutions

- High mechanical strength

- approved for foodstuffs (SIPERM® R, SIPERM® HP and SIPERM® HP antistatic)

- High heat resistance (SIPERM® R and SIPERM® B)

- High chemical resistance

- Long service life

- Simple installation

Our aeration elements are available in a variety of different designs: aeration pads and spots, circular blanks, tubes or funnels with standard or customized fastening – dimensions and designs on request.

We are a member!

Tridelta Siperm GmbH is a member of the German Bulk Solids Industry Association e.V

Ready-to-install ventilation elements

Ready-to-install aeration elements are an important component in bulk material handling. These components can be easily integrated into existing systems and do not require regular maintenance. Typical designs are aeration pads in standardized dimensions such as 125 × 250 mm or 125 × 500 mm as well as aeration spots with diameters of 80, 100 or 105 mm. SIPERM® R (1.4404) is the preferred material. Information on standard sizes and technical values can be found in the “Fluidization” information sheet.

Other dimensions are manufactured on a project-specific basis.

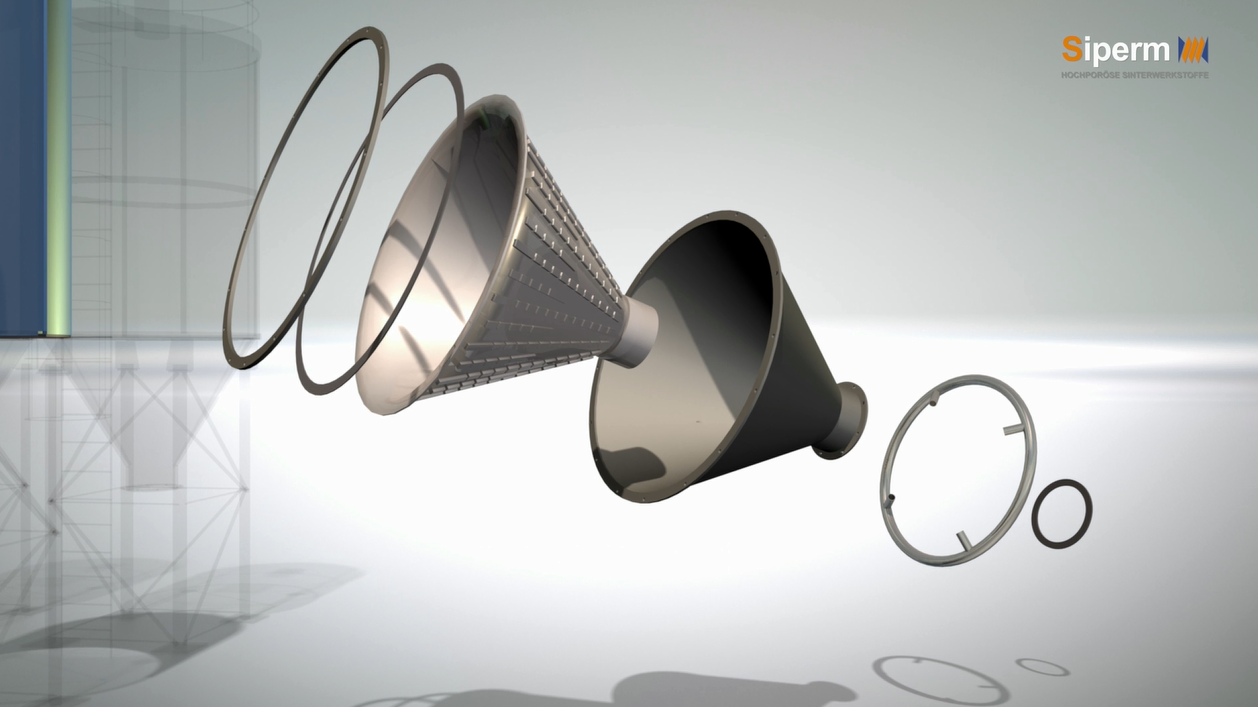

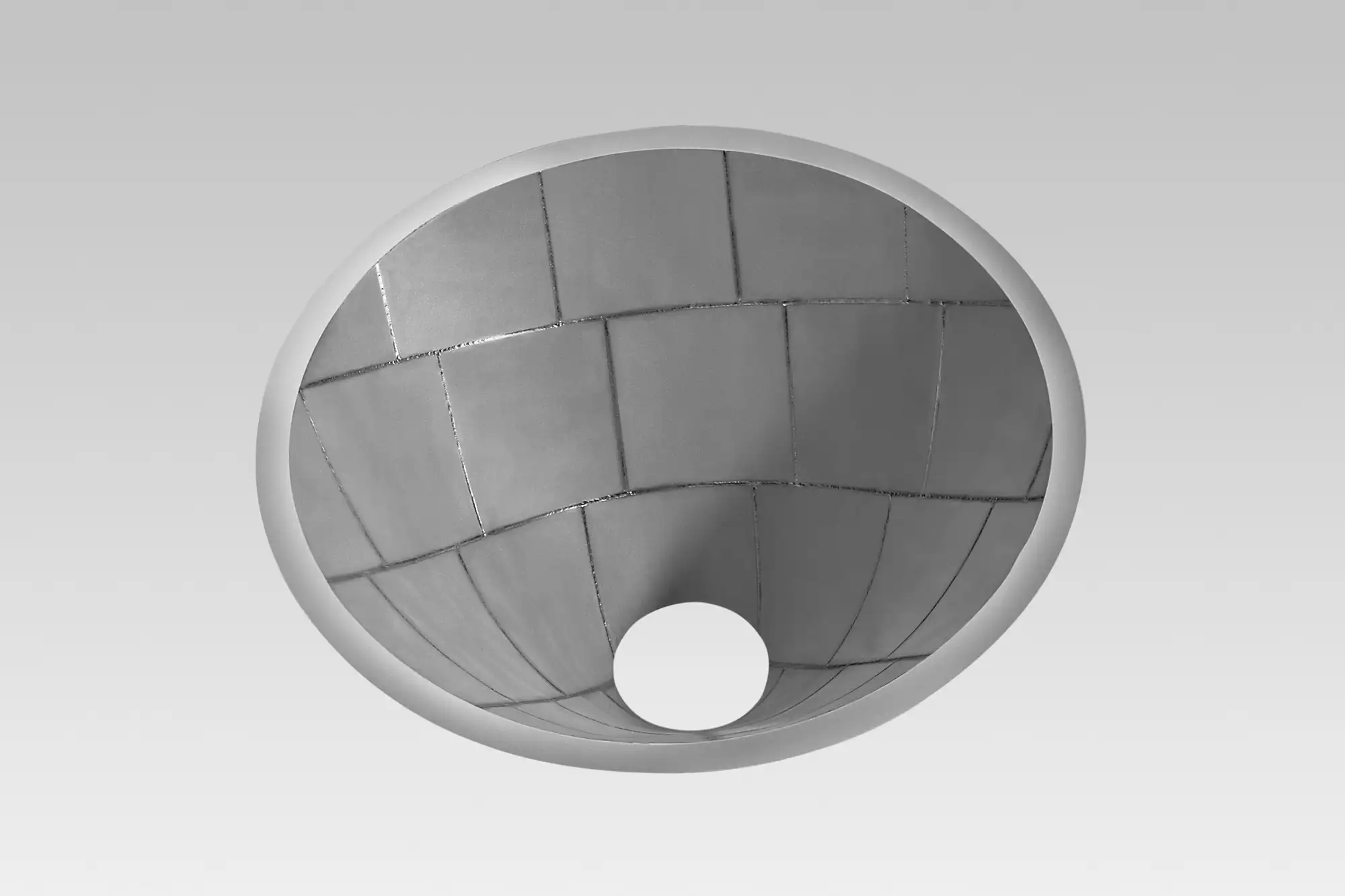

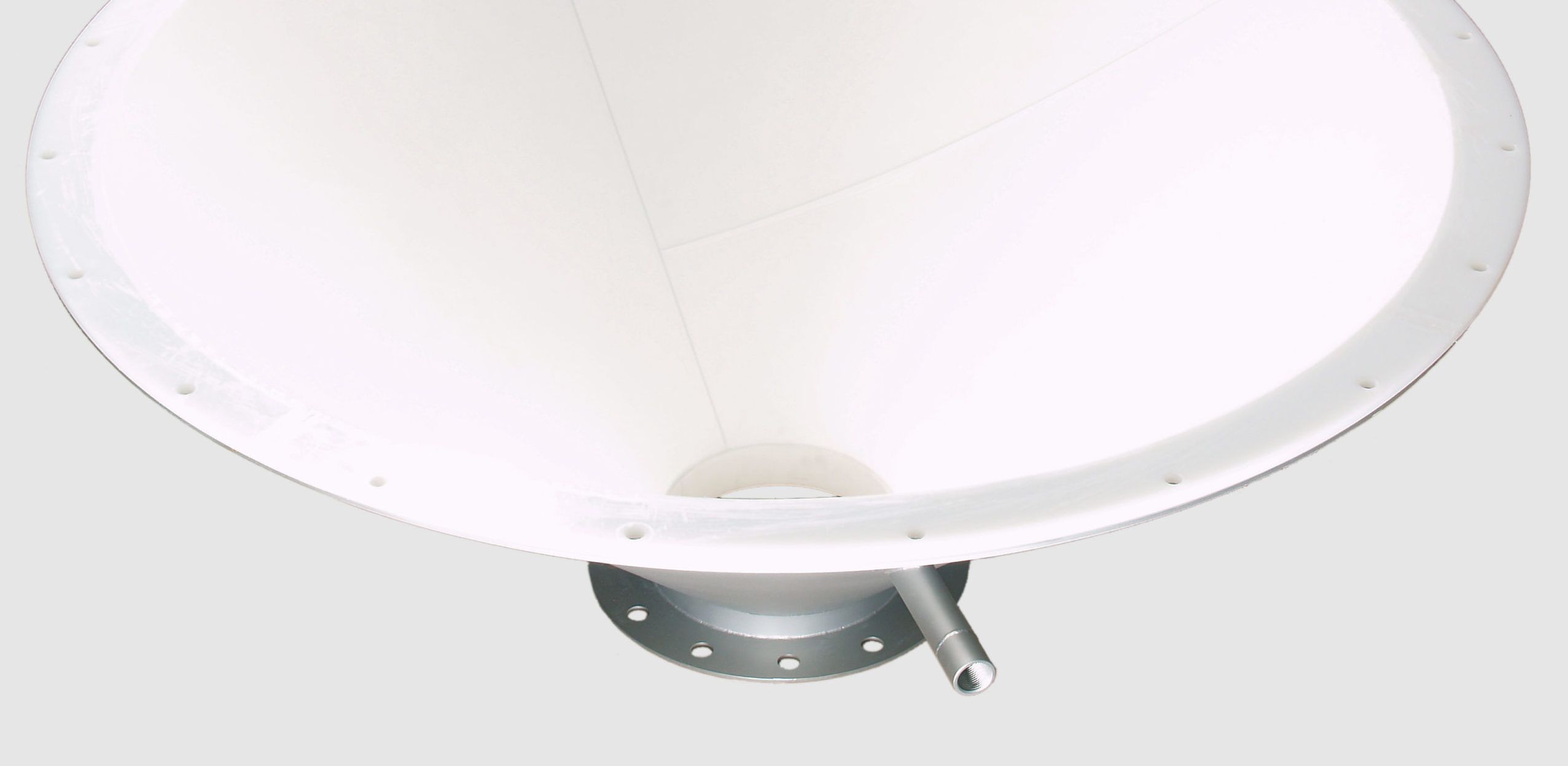

Tailor-made fluidizing floors

In addition to standard components, tailor-made aeration hoppers, fluidizing trays and inserts are also available. These elements are manufactured from SIPERM® R, SIPERM® B, SIPERM® HP or HP antistatic and adapted to the respective system conditions. The porous surface brings movement into the critical areas of a bulk solids container and ensures that clumps and deposits are dissolved. Thanks to their geometry and defined porosity, they bring movement into critical areas of the bulk material and improve the material flow. The components can be adapted to different shapes of silos, hoppers or conveyor systems, thus enabling precise design of the gas distribution.

SIPERM® materials are used in industrial bulk material handling to improve material flow, deaeration and process stability. The porous structure of the aeration elements distributes the gas flow evenly so that fine-grained or poorly flowing bulk materials are reliably loosened. This supports controlled discharge from silos and hoppers, prevents bridging and stabilizes the overall process. Suction pipes also enable the removal of trapped air or the targeted compaction of the material. Tailor-made aeration hoppers and fluidizing trays complete the portfolio for demanding system requirements. The combination of defined porosity, robust materials and ready-to-install components ensures reproducible results in fluidization, homogenization, cooling, drying and bulk material compaction.

The main advantages of the aeration elements include: an adjustable pore size, uniform air flow over the entire surface, robust and structurally simple solutions, high mechanical strength and the possibility of use in demanding media and temperature ranges. SIPERM® R, SIPERM® HP and HP antistatic are also approved for contact with food, while SIPERM® R and SIPERM® B offer high heat resistance. The service life of the components is long thanks to the stable sintered structure, and they can generally be installed without the need for complex conversions.

The elements are available in numerous variants and can be designed with specific fastening systems on request. This enables targeted integration into different system concepts, regardless of whether new projects or retrofits are involved. The combination of standardized dimensions and tailor-made solutions creates a wide range of options for reliably loosening, moving, deaerating or homogenizing bulk materials.

Fluidization and discharge of fine bulk solids

Bulk materials with small grain fractions tend to compact or stick together. This often results in stable deposits in the silo or hopper that block the discharge. In such cases, aeration bottoms, aeration pads or spots are used to loosen the material evenly. The porous surface distributes the gas flow over a wide area, significantly reducing friction and cohesion in the material bed. The flow does not occur selectively, but through the closed porous surface. This creates a reproducible process in which the bulk materials can flow off evenly.

Operation is carried out with dry, clean air or other suitable media. The required gas flow depends on the material properties, the surface area of the aeration elements and the respective system configuration. For fully lined containers, the volume flows are typically in the double-digit to triple-digit range per square meter and hour. In systems with partial lining, higher values may be required as the ventilated area is smaller.

Particularly in large silos, the ventilation is divided into sectors. Each sector can be controlled individually to initiate or stabilize material movement in a targeted manner. This reduces gas consumption and enables adjustments to be made to different filling levels. Integration into existing systems is comparatively simple, as SIPERM® elements are available in standardized or customer-specific mountings.

Homogenization of bulk materials

The aim of homogenization is to mix or stabilize the material bed evenly without mechanical intervention. Gas is introduced evenly through the porous surface, which loosens the material locally and equalizes areas of varying density. The process is suitable for powders with varying grain moisture or for bulk materials that tend to settle. The homogeneous gas distribution prevents individual zones from being excessively loosened, as can occur with nozzle structures.

Depending on the requirements, large aeration trays or segmented inserts can be used. For products with low flowability, the process is operated at intervals to generate local material movement. This extends the service life of the system and reduces the risk of uncontrolled material movements.

Cooling and drying via porous ventilation surfaces

Another area of application is the cooling and drying of bulk materials. The porous structure allows dry air or another medium to flow through the material over a wide area. This allows moisture to be removed evenly or heat to be dissipated. This is particularly relevant for temperature-sensitive materials or processes in which a defined residual moisture content is required.

SIPERM® R and B are suitable for more thermally demanding processes due to their temperature resistance, while SIPERM® HP is used where lower temperatures and flexible geometries are required. Uniform gas distribution prevents local overheating or one-sided drying.

Deaeration and suction of bulk materials

Fine-grained bulk materials often contain a considerable volume of air. When filling containers, air pockets are created which loosen the material or prolong the filling process. During emptying, trapped air ducts hinder even discharge. Suction pipes and porous inserts made of SIPERM® materials are used to control these effects.

Extraction takes place over the entire surface of the pipe or component. The porous structure allows air to pass through while particles remain in the material bed. This allows air pockets to be reliably removed from sacks, big bags or silo containers. The bulk material is compacted evenly without the need to apply mechanical forces. Due to their strength, SIPERM® R and B are suitable for higher negative pressures, while SIPERM® HP is used where flexible geometries or high chemical resistance are required.

Suction elements are also used for decanting when highly dusty products are processed. The uniform air intake along the entire length of the component prevents the bulk material from being sucked in locally, as is often the case with perforated pipes. Process stability is increased and the proportion of fine dust in the working environment is reduced.

Bulk material compaction with SIPERM® materials

In some applications, targeted compaction of the material is required – for example for further processing, to reduce the transport volume or for defined process steps. Vacuum compaction rollers and suction pipes made from SIPERM® are used here. The components extract air from the bulk material during mechanical processing, thereby increasing the material density.

With compaction rollers, the bulk material is first sucked in via a roller coated with SIPERM® R and pre-compacted. Further compression then takes place in the roller gap. The result is a uniformly compacted product that is easier to transport or process. The high compressive strength of the stainless steel material enables long-term use even under demanding loads.

Suction pipes fulfill a similar function, but without the mechanical compaction part. They are immersed directly into the bulk material and remove excess air. This reduces the volume of the material and allows it to be stored or packaged more efficiently. The uniform air absorption over the entire surface prevents localized constrictions or material jams.

Material selection and durability

The choice of suitable SIPERM® material is crucial for all the applications mentioned. SIPERM® R made of stainless steel 1.4404 offers high temperature resistance, strength and chemical stability. This variant is preferably used in areas where high mechanical loads or thermal conditions occur.

SIPERM® B made of bronze is characterized by low pressure losses and a very homogeneous pore structure. This is advantageous when uniform gas flows and moderate temperatures are required. SIPERM® HP – including HP antistatic – is used when the focus is on flexible geometries or special chemical requirements.

Contact

We are happy to advise you – simply contact us by phone, via email or by using our contact form.

Service

Tridelta Siperm GmbH

Ostkirchstr. 177

44287 Dortmund, Germany