Custom solutions for demanding applications

Homogenization

Our Address

Tridelta Siperm GmbH

Ostkirchstr. 177

44287 Dortmund, Germany

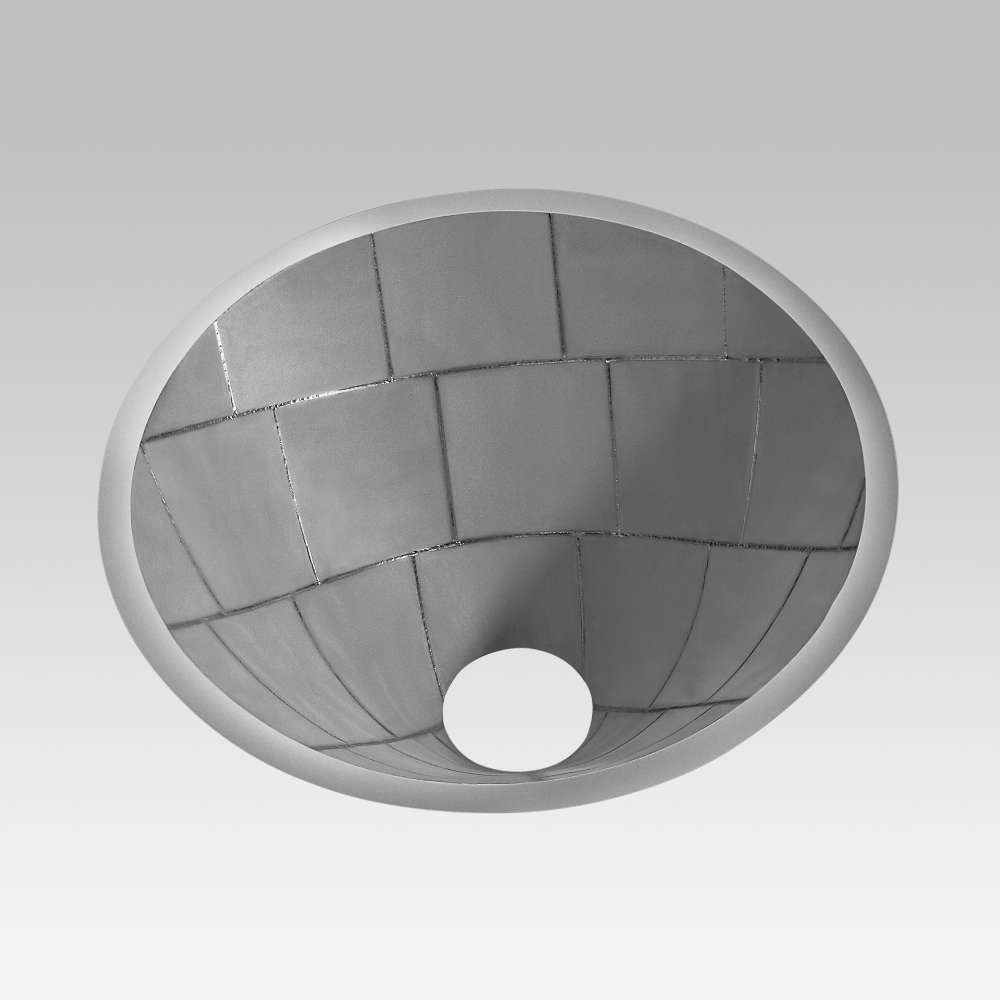

Homogenization with porous SIPERM® fluidizing trays

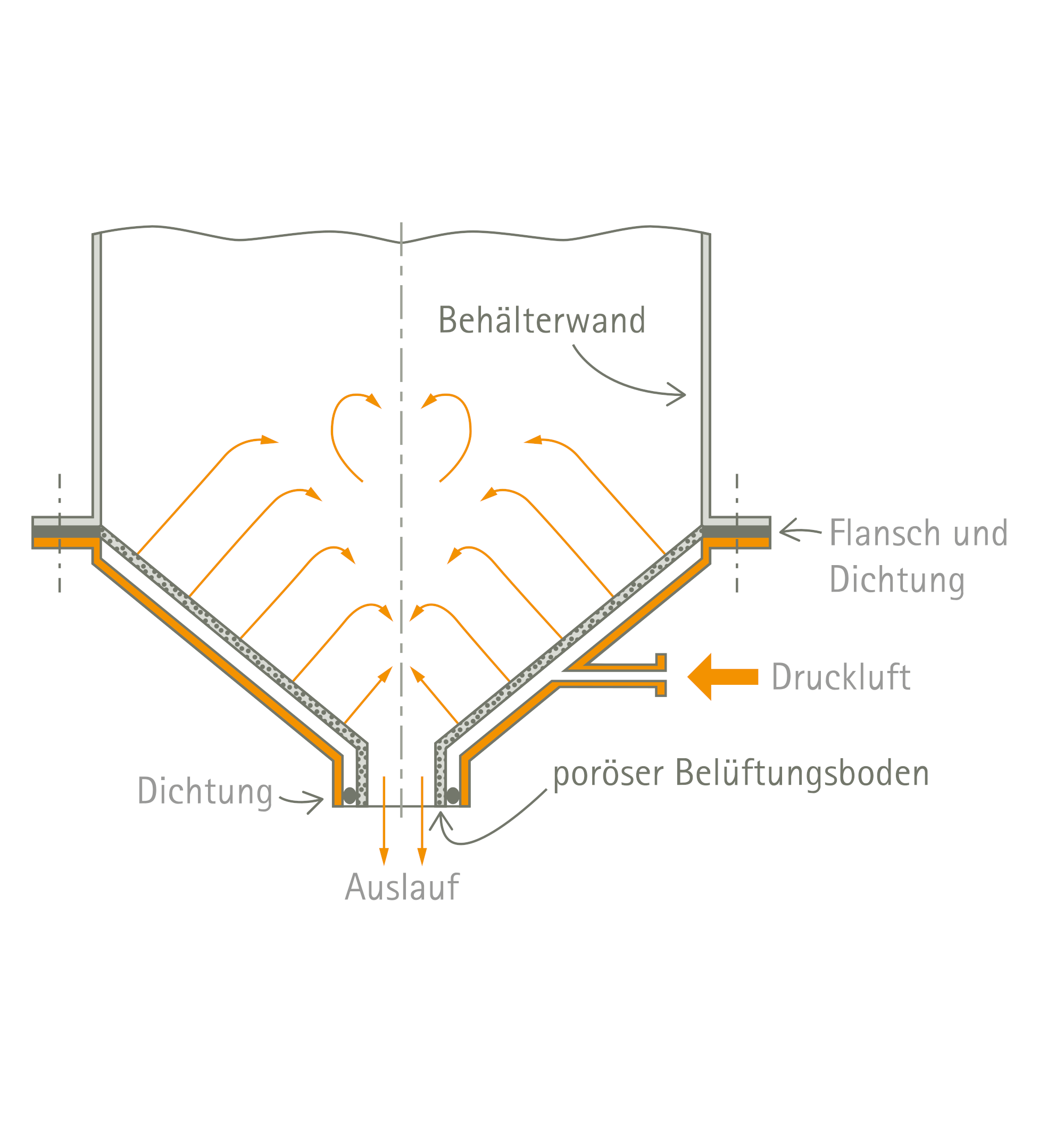

The homogenization process

Homogenization refers to a particularly strong fluidizing process in which the homogenizing base is subjected to a very high air flow. The aim is to completely fluidize the entire product or two or more different products with similar powder particle sizes. This achieves a uniform mixture of all components.

The bottoms of homogenizing silos are completely lined with porous plates. When commissioning the system, the air speed must be adjusted so that a uniform fluidized bed is formed. In this layer, the bulk material is loosened up to such an extent that individual particles can change their position over smaller or larger distances. This enables comprehensive mixing within the silo.

A fluidized bed is a fine-grained solid layer that is set in motion by a flowing fluid (e.g. air). The bulk material layer is fluidized, which overcomes frictional forces and static compaction.

Areas of application for homogenizing trays

Homogenizing trays are particularly suitable for uniform mixing:

-

of powders with comparable particle sizes and densities

-

of powders from different production batches

-

for applications in which uniform product quality is required

Thanks to intensive fluidization, even inhomogeneous starting products can be processed into a homogeneous end product. The use of homogenization technology therefore improves the reproducibility of product properties and increases process efficiency.

Application limits and operating parameters

Homogenization requires a precisely metered air supply in terms of pressure, temperature and throughput. When a silo floor is completely lined with SIPERM® panels, typical air flow rates are in the range of 100-300 m³/(m²-h). For applications with partial areas, e.g. in aeration cushions, significantly higher quantities may be required.

Prerequisites for stable operation:

-

Uniform particle size distribution (ideally < 200 µm)

-

Similar bulk densities of the components to be mixed

-

Dry, dust-free supply air (e.g. with pre-filtration)

-

Operating medium free of grease and oil

-

Controllable air supply via sectors for mixing even with large silo diameters

Advantages of the process

-

Consistent product quality thanks to complete homogenization

-

Segregation is effectively prevented

-

Suitable for retrofitting in existing systems

-

No additional mechanical stirring or mixing required

-

Can also be used for large silo volumes (sector control)

Typical applications

- Homogenization of plastic powders from different production batches

-

Mixing premixes or additives with base powders (e.g. in the food, chemical or building materials industries)

-

Production of uniform batches for downstream processes (e.g. extrusion, tableting, thermal treatment)

-

Support in avoiding segregation in logistics processes

Contact

We are happy to advise you – simply contact us by phone, via email or by using our contact form.

Service

Tridelta Siperm GmbH

Ostkirchstr. 177

44287 Dortmund, Germany