Custom solutions for demanding applications

Filtration of gases

Our Address

Tridelta Siperm GmbH

Ostkirchstr. 177

44287 Dortmund, Germany

Filtration of gases with porous sintered materials

Classification of gas filtration

The filtration of gases is an essential process in numerous industrial applications where particulate impurities need to be removed from gaseous media or defined flow conditions need to be created. It serves both to protect system components and to ensure stable process conditions.

In contrast to the filtration of liquids or polymer melts, gases are compressible media. Pressure, temperature and volume flow are directly related and have a significant influence on the flow behavior of porous filter elements. Accordingly, the design, pore structure and filter concept differ fundamentally from other types of filtration.

Porous sintered materials are used in gas filtration when a uniform, reproducible flow, defined separation limits and high mechanical stability are required. SIPERM® materials allow the pore structure to be precisely adapted to the respective requirements.

Typical tasks in gas filtration

Gas filtration fulfills different functions in industrial applications, which are often combined:

-

Separation of solid particles from process or ambient gases

-

Protection of sensitive components such as sensors, valves or measuring devices

-

Reduction of wear and malfunctions

-

Stabilization of the gas flow upstream of downstream processes

-

Compliance with defined purity requirements

Depending on the application, the focus is either on pure particle separation or on influencing the flow behavior. Especially with low particle concentrations or low pressure differences, a homogeneous pore structure is crucial for uniform filtration.

Requirements for porous filters in gas filtration

The filtration of gases places specific demands on porous filter materials, which result from the compressibility of the medium and the respective operating conditions.

Flow behavior and pressure loss

In gas filtration, even a slight change in the pore structure has a significant effect on the pressure loss. The filter elements must be designed in such a way that the gas flow is distributed evenly and no local flow peaks occur. A defined porosity is a prerequisite for this.

Mechanical stability

Porous filter elements in gases are often exposed to pulsating pressure loads. The structure must remain dimensionally stable even under changing pressure conditions in order to ensure constant filtration properties.

Temperature and media resistance

Depending on the application, increased temperatures or chemically contaminated gases may occur. The filter material must be able to be used permanently under these conditions without losing its function.

Function integration

In many applications, the porous filter performs additional tasks in addition to filtration, such as calming the gas flow or protecting sensitive components from mechanical damage.

Suitable SIPERM® materials for gas filtration

In the filtration of gases, the focus is less on absolute separation performance and more on controlled flow behavior in conjunction with defined particle retention. Homogeneous flow, stable pressure loss and functional reliability under changing operating conditions are crucial.

SIPERM® R – porous stainless steel in gas filtration

SIPERM® R is used in gas filtration where mechanical stability, temperature resistance and functional reliability are required. The porous stainless steel structure enables an even distribution of the gas flow over the entire filter surface and prevents local flow peaks.

A key area of application is the protection of sensitive components, for example in measuring and analysis devices. The homogeneous pore structure calms the gas flow while reliably retaining particulate impurities. In safety-relevant applications, SIPERM® R can also be used as a flame arrester if this is provided for in the design.

SIPERM® HP – porous polyethylene for gaseous media

SIPERM® HP is used in gas filtration where chemical resistance, low weight and defined gas permeability are paramount. The material is suitable for applications with moderate temperatures where metallic filters are not required.

In gas filtration, SIPERM® HP is often used as a protective filter, for example to retain dust particles or as mechanical protection for sensitive components. The uniform pore structure supports a stable flow with comparatively low pressure loss.

SIPERM® B – porous bronze in selected gas filtration applications

SIPERM® B is used in gas filtration exclusively in applications where the focus is on low pressure losses and there are no increased thermal or safety-related requirements. The homogeneous pore structure of the porous bronze enables a uniform flow at low differential pressures.

Typical applications are simple gas filter or pre-filter applications with dry, non-aggressive gases. SIPERM® B is not used for applications with high temperatures, pulsating pressure conditions or safety-relevant functions.

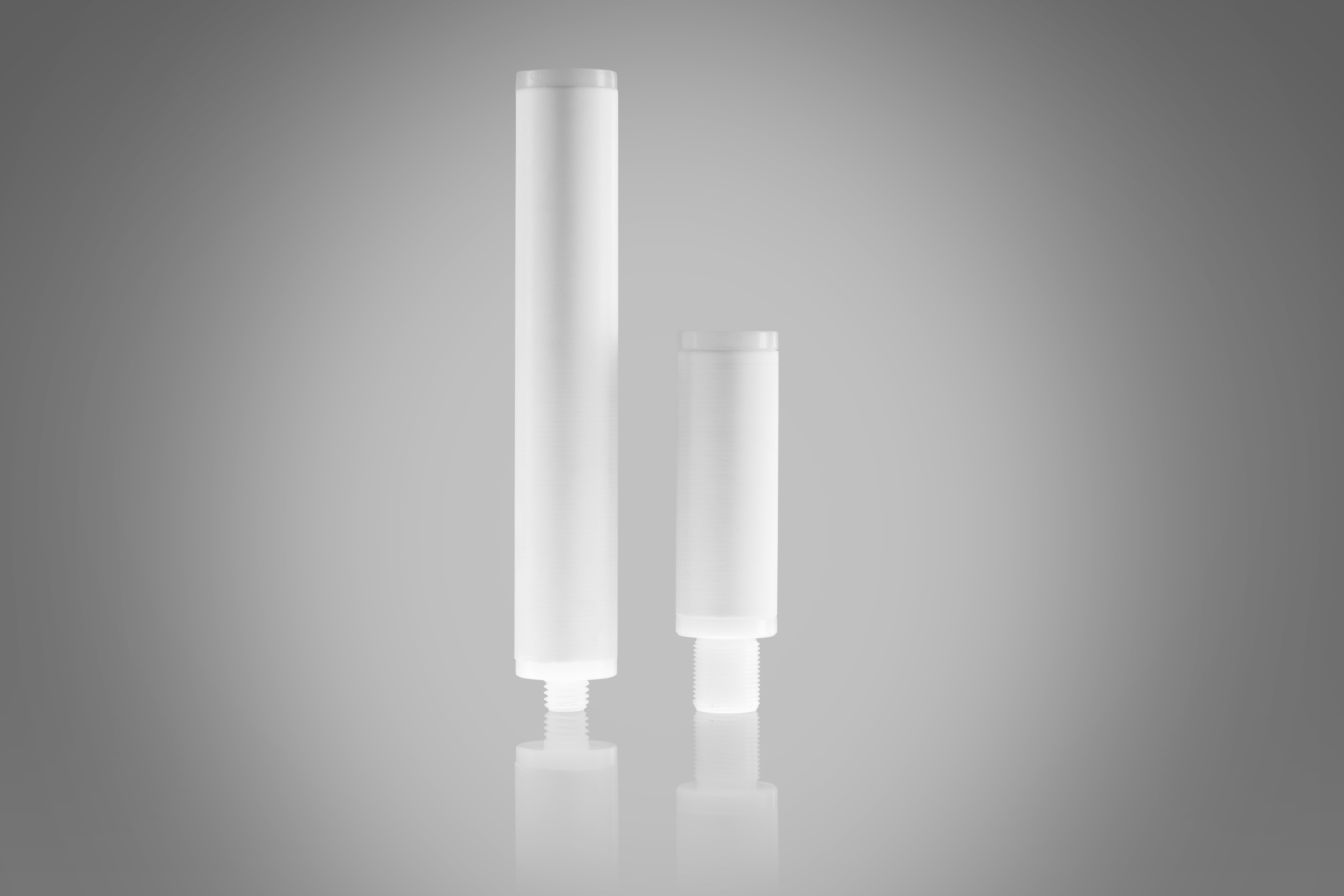

Typical designs and applications in gas filtration

Porous SIPERM® materials can be manufactured in different geometries to adapt them to specific gaseous applications.

-

Filter caps and protective bodies for sensors and measuring devices

-

Filter inserts for dust separation in gas streams

-

Porous inserts to calm the flow

-

Molded parts for integrated filter functions in housings or fittings

The respective design is selected depending on the flow rate, permissible pressure loss, installation space and functional requirements.

Contact

We are happy to advise you – simply contact us by phone, via email or by using our contact form.

Service

Tridelta Siperm GmbH

Ostkirchstr. 177

44287 Dortmund, Germany