Custom solutions for demanding applications

Security technology

Our Address

Tridelta Siperm GmbH

Ostkirchstr. 177

44287 Dortmund, Germany

Explosion protection in industrial applications with porous sintered materials

Classification and technical significance of explosion protection

Explosion protection is a key issue in industrial applications where flammable gases, vapors or dusts can occur. In many processes, explosive atmospheres do not occur permanently, but temporarily or locally, for example when filling, emptying, conveying or degassing media. The aim of explosion protection is to prevent the development of hazardous conditions or to technically limit their effects.

In technical terms, a distinction is made between preventive and constructive measures. Preventive measures are aimed at avoiding explosive atmospheres or effective ignition sources. Constructive measures limit the spread or effects of an explosion within systems and assemblies.

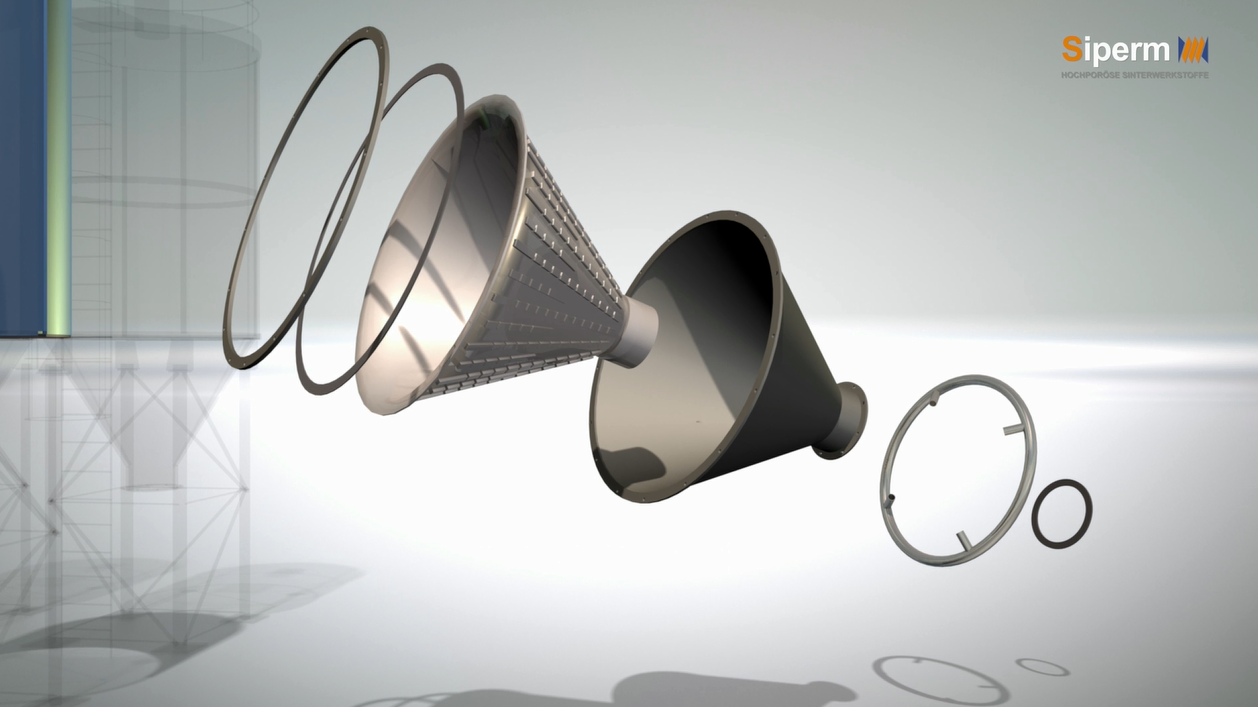

Porous sintered materials are used in explosion protection as functional, passive components. They do not assume an active protective function, but support constructive protection concepts through defined gas flow, pressure relief or flame retention. SIPERM® sintered materials are used in this context where structured gas permeability and high mechanical stability are required.

Role of porous SIPERM® materials in explosion protection

Porous sintered materials act as structured barriers or defined passage elements in explosion protection. Their pore structure allows gases to pass through under normal operating conditions, while at the same time they can act as a physical barrier for flame fronts, hot particles or pressure surges.

SIPERM® components assume a clearly defined function within an overall protection concept. They do not replace a safety assessment and do not represent an independent explosion protection device, but are part of constructive measures that are designed on the basis of a risk assessment.

They are used in particular where gas flows need to be routed in a controlled manner without flames or explosion-related pressure waves being able to spread unhindered.

Systematics of explosion protection and classification of porous SIPERM® sintered materials

Safety engineering is used to prevent damage to people, plant and property caused by technical products, industrial equipment and technical processes. In explosion protection, the measures used for this purpose are methodically divided into primary, secondary and tertiary explosion protection. This classification describes different protection goals within an overall concept and is to be understood independently of individual products.

Porous SIPERM® sintered materials are used in this context as passive, constructive elements. Depending on the application, they support measures in all three areas of explosion protection. SIPERM® materials do not replace safety-related design or normative evaluation, but are integrated into existing explosion protection concepts as application-related, constructive elements.

Primary explosion protection – avoidance of explosive atmospheres

The aim of primary explosion protection is to prevent the formation of an explosive atmosphere. This is achieved, among other things, through controlled gas flow, the reduction of dust turbulence or the use of inerting media.

SIPERM® components are used here, among other things, for

-

Antistatic fluidization of powders and bulk solids

-

Uniform inertization of process areas or system parts

-

Controlled gas flow to reduce local concentrations

Thanks to their defined porosity, SIPERM® components enable a uniform gas flow without punctual flow effects or uncontrolled particle movements. They therefore help to prevent explosive atmospheres as part of preventive safety measures.

Secondary explosion protection – avoidance of effective ignition sources

Secondary explosion protection comes into play where explosive atmospheres cannot be safely excluded. The aim is to avoid effective ignition sources or to detect dangerous conditions at an early stage.

Porous SIPERM® sintered materials are used in this context in applications such as

-

Gas detection and monitoring systems,

where a defined gas permeability and the protection of sensitive components are required

The SIPERM® components do not have an active monitoring function. They serve as design elements for controlled gas flow and for the protection of downstream sensors and systems.

Tertiary explosion protection – constructive explosion protection

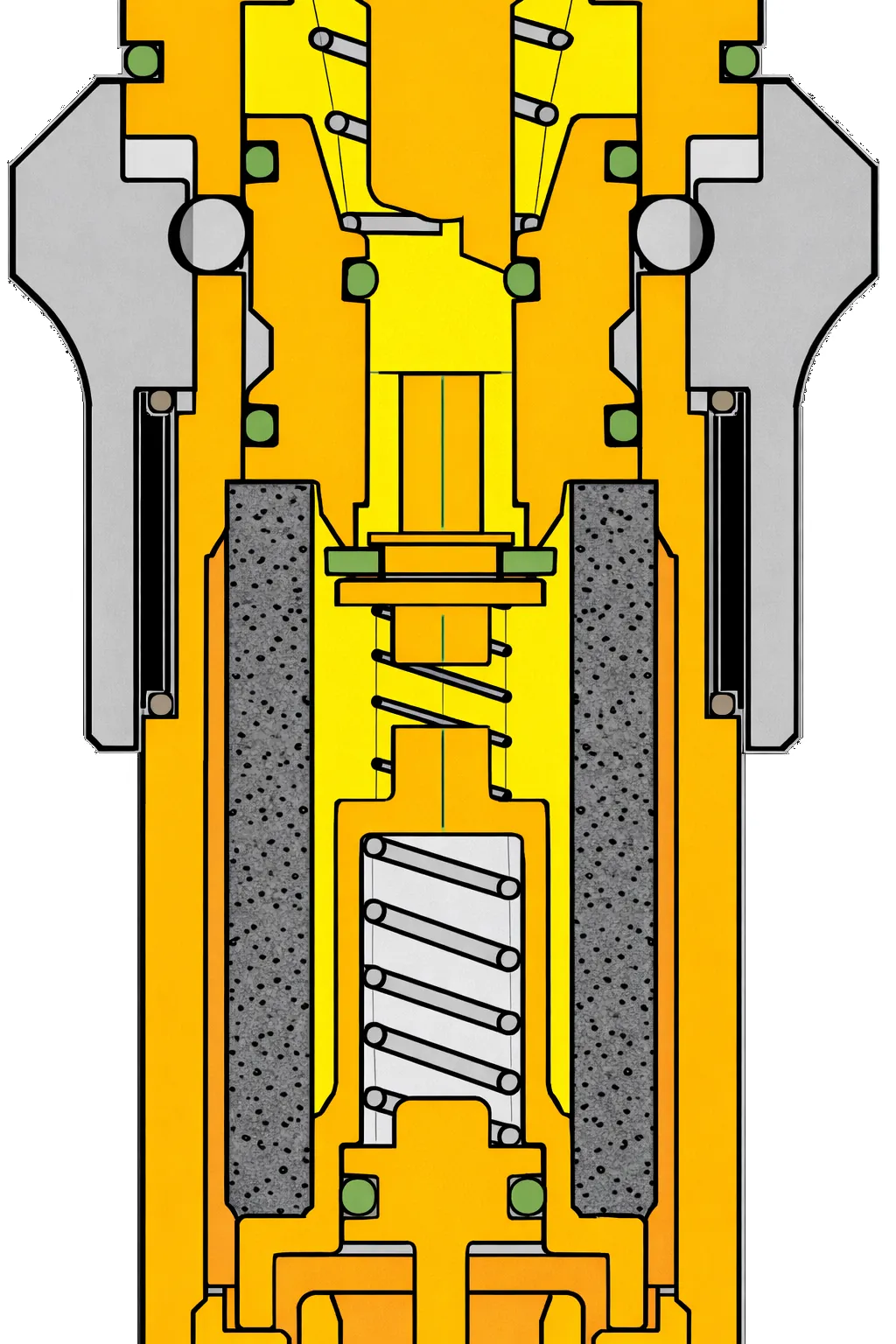

Tertiary explosion protection comprises constructive measures that are designed to limit the effects of an explosion. These include components and systems that prevent the spread of flames, dissipate pressure in a targeted manner or safely conduct explosive media.

SIPERM® materials are particularly suitable for this area:

-

Flame arresters as part of constructive protective measures

-

Pressure relief devices with defined gas flow

-

Pneumatic conveying of explosive dusts with controlled degassing

Thanks to their mechanical stability and defined pore structure, SIPERM® components can be used as part of constructive protective measures, for example to limit flame fronts or for controlled pressure dissipation.

Technical operating principles of porous sintered materials in explosion protection

Porous sintered materials do not assume an active safety function in explosion protection, but act as constructive, physically defined functional elements. Their effect results from the combination of pore structure, material and component geometry. These parameters determine how gases, pressure and thermal effects are guided or limited within a system.

In explosion protection, porous SIPERM® sintered materials are used where gas-permeable structures are required, but at the same time an uncontrolled spread of flames, hot particles or pressure surges must be prevented.

Structured gas permeability

The defined pore structure of porous sintered materials enables the controlled passage of gases under operating conditions. Compared to open cross-sections, the gas flow is evenly distributed over many small pores. This prevents local flow peaks and calms gas movements.

This structured gas permeability is an essential basis for applications in explosion protection, such as inerting, controlled ventilation or as a component of gas ducting systems in potentially explosive atmospheres.

Flame retention due to pore structure

With the right design, porous sintered materials can act as a flame barrier. The fine pore channels limit the spread of a flame front by dissipating heat and reducing the flame temperature locally. The pore size, wall thickness and thermal conductivity of the material are decisive for this.

In this context, SIPERM® components are not understood as independent flame arresters in the normative sense, but as constructive elements that can contribute to limiting the spread of flames in suitable applications.

Limitation of pressure and impact effects

In the event of an explosion, high pressure and flow peaks occur in the short term. Due to their flow resistance and mechanical stability, porous sintered materials can help to dampen or dissipate pressure peaks in a controlled manner.

The effect does not result from active pressure control, but from the physical property of the porous body to distribute and restrict flows. The mechanical design of the component is of central importance here.

Passive function in the overall system

All the active principles described are based on passive physical effects. Porous SIPERM® sintered materials do not generate a protective effect independently of the system, but develop their function exclusively in conjunction with the respective system configuration and the specified process conditions.

They are therefore always part of an overall explosion protection concept and are no substitute for safety assessments or active protection systems.

Functional applications of porous sintered materials in explosion protection

Porous sintered materials are used in explosion protection where gases or dusts have to be guided, limited or discharged in a controlled manner under defined conditions. The focus is not on classification according to protection levels, but on the specific technical function that the component performs within a system.

SIPERM® sintered materials are used as passive, structural elements in potentially explosive atmospheres. They are part of higher-level protection concepts and are designed for specific applications.

Gas routing and inertization

In potentially explosive areas, uniform gas flow is crucial in order to avoid local concentrations of flammable gases or vapors. Porous sintered materials enable gas to be distributed over a wide area and prevent localized gas ingress at high flow rates.

SIPERM® components are used here to introduce inert gases evenly or to guide process gases in a controlled manner. The porous structure supports smooth gas flow and reduces flow peaks without using active control mechanisms.

Flame retention and flame barriers

Porous sintered materials can be used as constructive flame barriers if flames are to be prevented from spreading to adjacent parts of the system. The fine pore channels limit the spread of flame fronts through heat dissipation and geometric restriction.

SIPERM® components take on a passive protective function and are used as part of structural measures. The effectiveness depends on porosity, wall thickness and material and must always be assessed on an application-specific basis.

Pressure relief and controlled venting

In the case of short-term pressure loads, such as those that can occur in the event of an explosion, controlled pressure relief is required. Porous sintered materials can help to dissipate pressure evenly and reduce local load peaks in appropriate designs.

The effect is based on the defined flow resistance of the porous body. SIPERM® components do not actively regulate the flow, but act as mechanically stable passage elements.

Conveying and degassing explosive dusts

In the pneumatic conveying of explosive powders and dusts, controlled gas flow is required in order to avoid dust turbulence and uneven pressure conditions. Porous sintered materials are used here as gas-permeable but dust-tight separating elements.

SIPERM® components enable the removal of trapped gases while the particles are safely retained. This enables stable conveying and degassing conditions to be achieved.

Protective and functional elements in potentially explosive atmospheres

Porous sintered materials are also used as protective or functional elements in assemblies that are operated in potentially explosive atmospheres. These include, for example, covers, separating elements or gas-permeable components to protect sensitive components.

The SIPERM® sintered materials take on a clearly defined, passive function and are tailored to the respective mechanical, thermal and fluidic requirements.

Design, standards and integration into explosion protection concepts

Porous sintered materials are not considered in isolation in explosion protection, but are designed as part of a higher-level overall safety concept. The components are selected and dimensioned on the basis of the respective risk assessment and the system-specific boundary conditions.

Application-related design

The design of porous SIPERM® sintered materials takes into account fluidic as well as mechanical and safety-related aspects. Decisive factors include

-

Type of explosive atmosphere (gas, vapor, dust)

-

Operating pressure and possible pressure peaks

-

Temperature range and thermal load

-

Required gas permeability or barrier effect

-

Installation situation and structural connection

Porosity, wall thickness and geometry are determined in such a way that the desired function is reliably fulfilled without creating additional risks.

Normative framework conditions

Explosion protection measures are subject to legal and normative requirements. Porous sintered materials themselves do not generally represent independent explosion protection devices, but are used as design components within systems.

Integration therefore always takes place in the context of applicable regulations and guidelines, for example as part of risk assessments and system-specific protection concepts. The responsibility for the safety assessment lies with the system operator or the system manufacturer.

Integration into existing explosion protection concepts

SIPERM® sintered materials are integrated into explosion protection concepts in order to constructively support defined functions such as gas flow, flame retention or pressure limitation. The components supplement active protection systems and organizational measures, but do not replace them.

Thanks to their passive mode of action, porous sintered materials can be reliably integrated into existing systems without introducing additional control or regulation mechanisms. Integration is carried out in close coordination with the technical requirements of the respective application.

Technical summary

Porous sintered materials are used in explosion protection as passive, constructive functional elements. They do not assume an active safety function, but support explosion protection measures through defined gas permeability, mechanical stability and a structured barrier effect. Their effect results from the combination of pore structure, material and component geometry.

SIPERM® sintered materials are used in various explosion protection-related functions, including gas flow and inerting, flame retention, pressure relief and the conveyance and degassing of explosive dusts. They are used as part of higher-level protection concepts and must always be designed for the specific application.

Assignment to primary, secondary or tertiary explosion protection is not based on the component itself, but on the respective function in the system concept. Depending on the design and installation situation, SIPERM® components can support measures in all three areas without replacing active control or protection systems.

Material selection, porosity and geometry are considered together in a safety-related context. Integration takes place on the basis of a risk assessment and in consideration of applicable normative and legal requirements. Porous SIPERM® sintered materials are therefore constructive components for implementing technical explosion protection measures in industrial applications.

Contact

We are happy to advise you – simply contact us by phone, via email or by using our contact form.

Service

Tridelta Siperm GmbH

Ostkirchstr. 177

44287 Dortmund, Germany