Custom solutions for demanding applications

Engineering & Development

Our Address

Tridelta Siperm GmbH

Ostkirchstr. 177

44287 Dortmund, Germany

Engineering & Development

Role of engineering and development at Tridelta Siperm

Engineering and development at Tridelta Siperm GmbH are focused on the application-oriented design of porous SIPERM® materials and components for a wide range of industrial applications. The focus is always on the specific technical requirements of the respective application and not on isolated material parameters.

The fields of application for porous SIPERM® materials include filtration, aeration and degassing, fluidization, bulk material handling, sound absorption, sensor protection, discharge aids, material transport and compaction as well as other safety and process engineering applications. The requirements for flow behavior, pore structure, mechanical strength, chemical resistance, temperature behavior and geometric design are correspondingly diverse.

Classification of the engineering approach

Engineering at Tridelta Siperm is not a standardized product development process, but a technical coordination process along real applications. The aim is to develop a functionally suitable and reproducible solution for each application that is suitable for the respective installation situation in terms of both material and design.

Key features of the engineering approach:

-

Consistently application-oriented development

-

Close technical coordination with the customer

-

Evaluation of material, porosity, geometry and installation situation in context

-

Consideration of operation, cleaning and reproducibility

-

Early involvement of production in development projects

Cross-material expertise

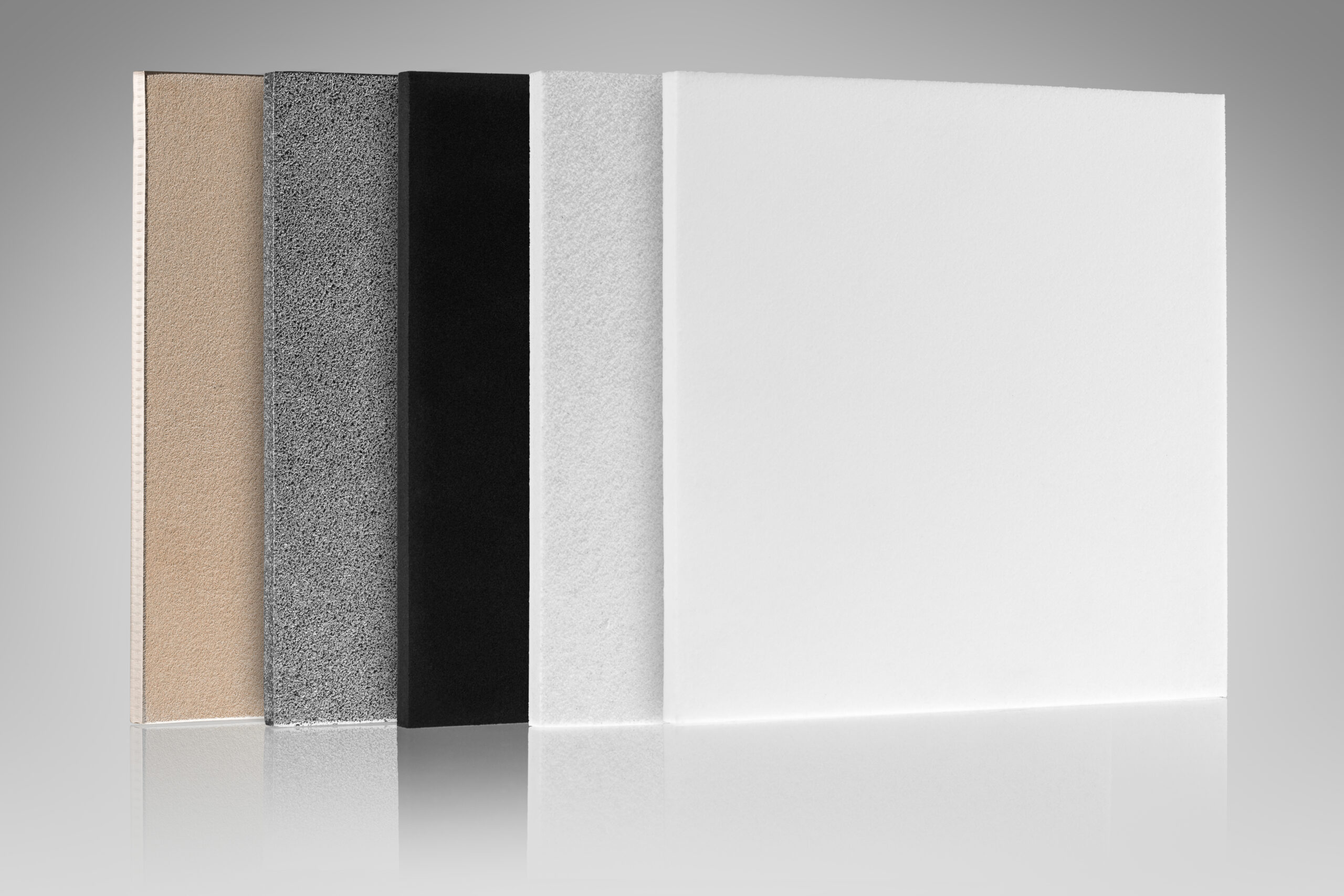

One of Tridelta Siperm’s unique selling points is that we produce porous stainless steel, porous bronze and porous polyethylene ourselves. This combination enables a cross-material view of applications.

For engineering, this means

-

Selection of the technically most sensible material independent of the material system

-

Comparison of metallic and polymer solutions for the same application

-

Adaptation of existing materials instead of compromise solutions

The material decision is therefore application-driven and is based on functional requirements such as flow rate, differential pressure, strength, temperature and media resistance as well as special boundary conditions.

Technical evaluation principles

A central component of the engineering process is the structured evaluation of the application. The following aspects, among others, are taken into account:

-

Type of medium (gas, liquid, bulk material)

-

Functional task of the porous component in the process

-

Mechanical loads during operation

-

Thermal and chemical boundary conditions

-

Geometric restrictions and installation situation

These factors are not considered in isolation, but are evaluated in the interplay of material, porosity and construction. This often results in application-specific individual solutions, especially for special applications.

Laboratory and development proximity to production

The development work is supported by a well-equipped laboratory. Microscopic examinations and material-related tests are used to analyze pore structures and evaluate functional relationships.

At the same time, we check at an early stage how a developed solution can be manufactured in a reliable and reproducible manner. Engineering and development at Tridelta Siperm are therefore closely interlinked with production and take the degree of automation and testability into account at an early stage.

Engineering methodology and technical design

Engineering at Tridelta Siperm is consistently application- and project-oriented. The starting point for every development is the technical understanding of the respective application and the media or materials used in it. Only on this basis is the selection of the suitable porous material and the structural design of the component or assembly made.

Analysis of media and process properties

Depending on the application, porous SIPERM® components have to meet very different requirements. An essential first step in engineering is therefore to analyze the relevant media and process properties.

These include, among others:

-

Particle size, particle shape and distribution of bulk solids

-

Density, flow behavior and compaction tendency

-

Dust development and ventilation behavior

-

Properties of gases or liquids in the process

-

Interactions between medium and material

These properties have a direct influence on the subsequent design of porosity, pore size, material thickness and geometry of the porous components, particularly for applications in the field of fluidization, bulk material handling, discharge aids, material transport or compaction.

Selecting the right SIPERM® material

The cross-material selection within the SIPERM® portfolio is based on the requirements analysis. As Tridelta Siperm manufactures porous stainless steel, porous bronze and porous polyethylene itself, the material decision can be made independently and exclusively application-driven.

The following criteria, among others, are taken into account:

-

Mechanical resilience and strength

-

Temperature resistance

-

Chemical resistance to media and cleaning processes

-

Flow rate and differential pressure requirements

-

Special boundary conditions such as food contact or detectability

Many projects show that standard materials alone are not enough. In these cases, material adaptations or combined solutions are developed in order to reliably fulfill the functional requirements.

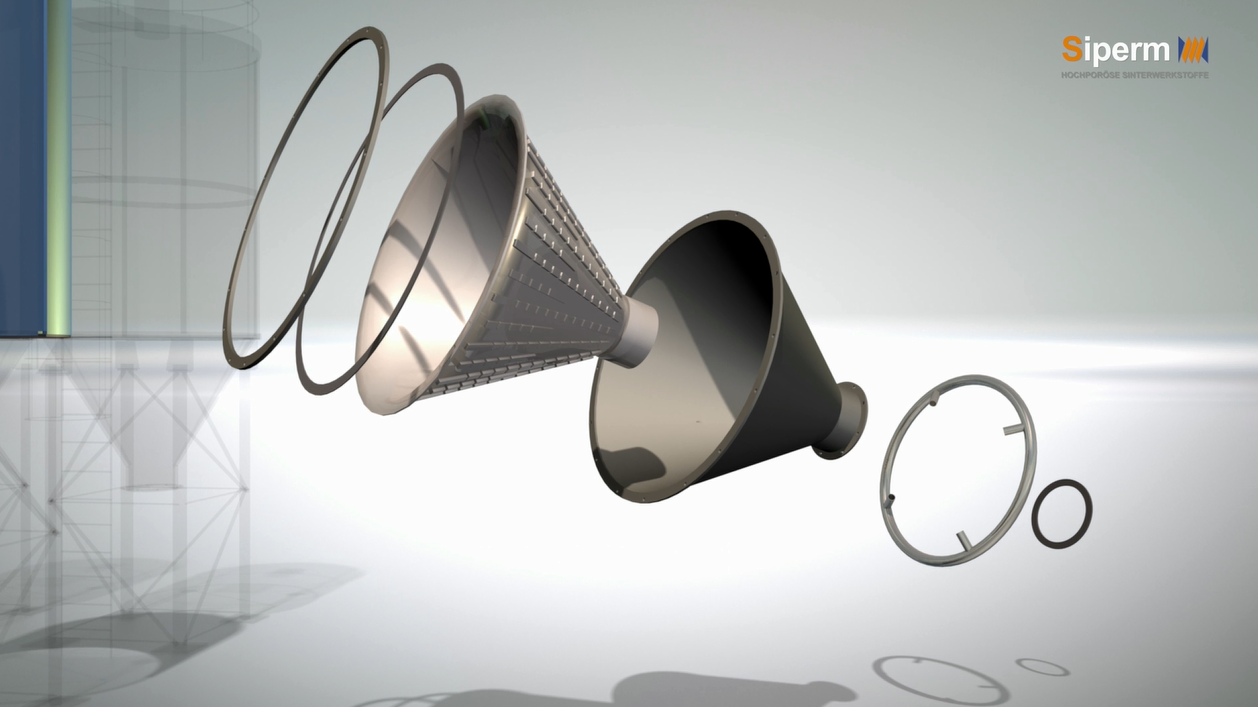

Design and technical support

The technical design is carried out in close cooperation between engineering, construction and the customer. The design department supports the implementation of customized solutions, taking into account dimensional specifications, tolerances and structural constraints.

Engineering at Tridelta Siperm is therefore not an isolated development step, but a continuous technical coordination process that combines requirements analysis, materials expertise and design implementation.

Material and process development

Material and process development at Tridelta Siperm is consistently application-driven. The aim is to specifically adapt or further develop existing porous SIPERM® materials if practical requirements cannot be adequately covered by standard designs. The focus is always on functional requirements from real applications.

The basis for this is the wide range of porous stainless steel, porous bronze and porous polyethylene, which cover different physical, chemical and mechanical properties. Within these material systems, there are many possibilities for varying pore size, porosity, structure and processing.

Further developments in the field of porous polyethylene

In the field of porous polyethylene components, several application-specific developments have been realized in recent years. One example is the hydrophilization of porous polyethylene, with which the wetting behaviour can be specifically adapted to the respective application. This allows the interaction between medium and material to be influenced, especially in applications with liquids or changing media conditions.

Another example is antistatic porous polyethylene. This version is used when electrostatic effects must be avoided or reduced during operation. The antistatic property is specifically implemented for applications with corresponding safety or process-related requirements.

In addition, SIPERM® HP FL-R, a porous polyethylene infiltrated with stainless steel particles, has been developed. This design enables detectability in food-safe environments and was implemented in response to increased requirements in plant engineering.

Adjustments for metallic porous materials

Specific adjustments are also made in the area of metallic materials when applications have conflicting requirements. With porous bronze, for example, multi-layer material structures can be realized.

These are used when both high flow rates and high particle separation are required, for example in filtration applications. By combining different pore structures within a component, functional properties can be staggered in a targeted manner. The design of such material structures is always application-oriented and carried out in close consultation with the customer.

Surface modifications and coatings

In addition to adapting the internal material structure, surface modifications were also implemented for porous components. Coatings were applied to the surface of porous polyethylene in particular in order to adapt the interaction between the carrier material and the surface to specific requirements.

The aim of these measures is not a general change in the material, but functional optimization within the respective application.

Prospects for material and process development

The development work is not limited to existing pore sizes or manufacturing processes. Tridelta Siperm is continuously working on evaluating further pore size ranges and new material and manufacturing processes.

This also includes processes that enable the rapid geometric implementation of simple components, for example to create functional samples or for initial customer tests. Material and process development at Tridelta Siperm should therefore be understood as a continuous technical development process that specifically extends existing materials and adapts them to new requirements.

Engineering in plant construction and series implementation

Porous SIPERM® materials are often used as functionally relevant components in plant engineering. Applications such as fluidization, discharge aid, material transport or compaction place special demands on the material, porosity, geometry and installation situation. In many cases, these are not standardized solutions, but individual solutions designed specifically for the application, which must be adapted to the respective bulk material and the system configuration.

Engineering at Tridelta Siperm therefore not only considers the selection of a suitable porous material, but also the geometric and structural design within existing or newly planned systems. Aspects such as installation space, load, fastening, inflow, pressure conditions and maintenance accessibility are systematically incorporated into the design.

On request, Tridelta Siperm supports customers in the early project phases and assists with both new designs and the integration of porous components into existing systems. This also includes retrofittable solutions, such as ventilation cushions or fluidization installations, which can be integrated without fundamental changes to the system.

Welded constructions made of porous SIPERM® materials

All SIPERM® materials can be used to produce welded constructions of any size and shape. Production is always carried out according to customer specifications and taking into account the respective application. Porous semi-finished products can be combined into larger assemblies and adapted to specific geometric requirements.

The engineers at Tridelta Siperm provide individual support in the design and construction of these welded structures. The geometry, dimensional specifications, tolerances and installation situation are taken into account, as is the subsequent function in the process. The aim is a technically robust solution that can be reliably integrated into existing or new systems.

Production-related development

Close coordination between development and production is an essential part of the engineering work. Even during the design phase, we check how a solution can be produced reliably and reproducibly. This is particularly important for high-volume applications.

In the production area, Tridelta Siperm optimizes the degree of automation of the production processes in order to be able to offer competitive products in the long term. At the same time, the quality and reproducibility of the processes are continuously improved. Depending on the product and application, automated 100% inspections can be implemented, both in terms of physical and optical quality characteristics.

Testing technology, reproducibility and customer-specific measuring methods

Quality assurance is an integral part of the development and production process. Tridelta Siperm is prepared to coordinate measuring devices and test procedures with customers and, if necessary, to implement customer-specific measuring methods.

This allows application-relevant features to be monitored, documented and reproducibly safeguarded in a targeted manner. Engineering and development at Tridelta Siperm therefore do not end with material selection or design, but cover the entire process from the application idea to reproducible series production.

Contact

We are happy to advise you – simply contact us by phone, via email or by using our contact form.

Service

Tridelta Siperm GmbH

Ostkirchstr. 177

44287 Dortmund, Germany