Custom solutions for demanding applications

Siperm® products

Our Address

Tridelta Siperm GmbH

Ostkirchstr. 177

44287 Dortmund, Germany

Product range

porous sintered materials and components for a wide range of industrial applications – standardized or custom-made

Overview of product types

Our materials

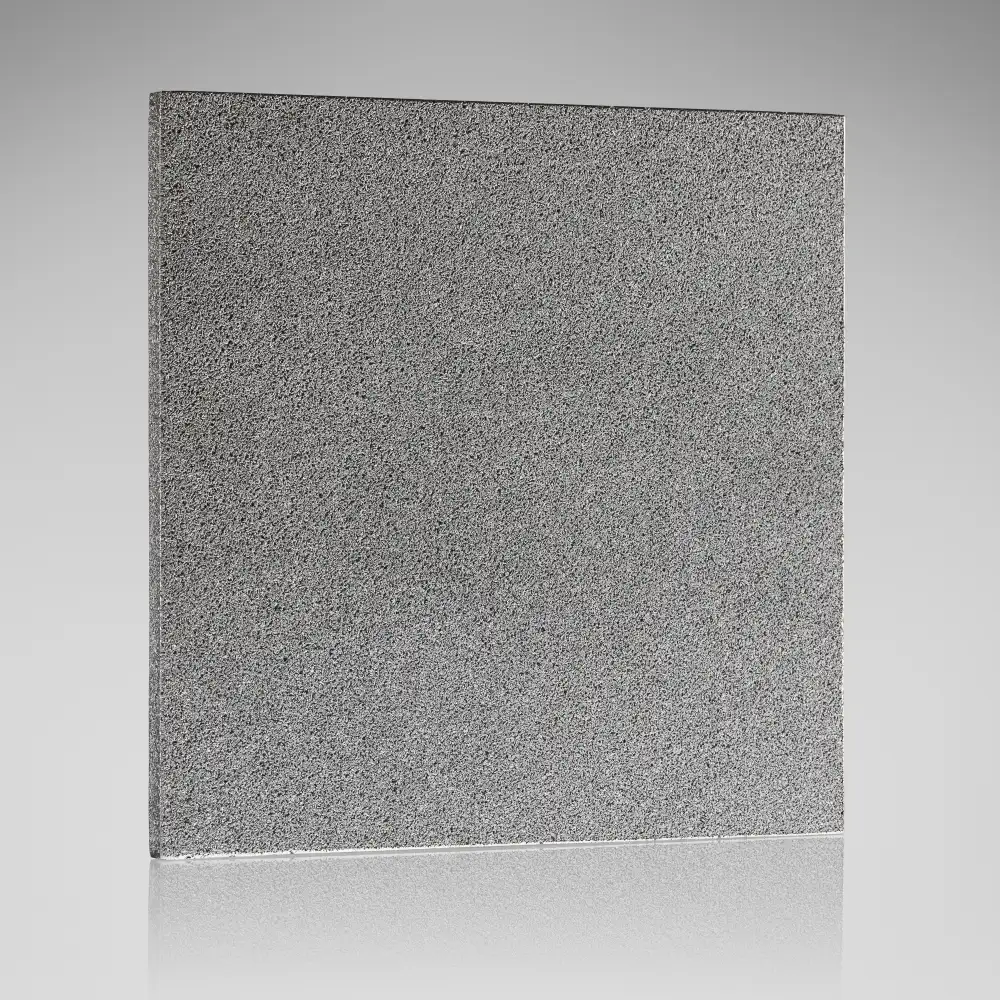

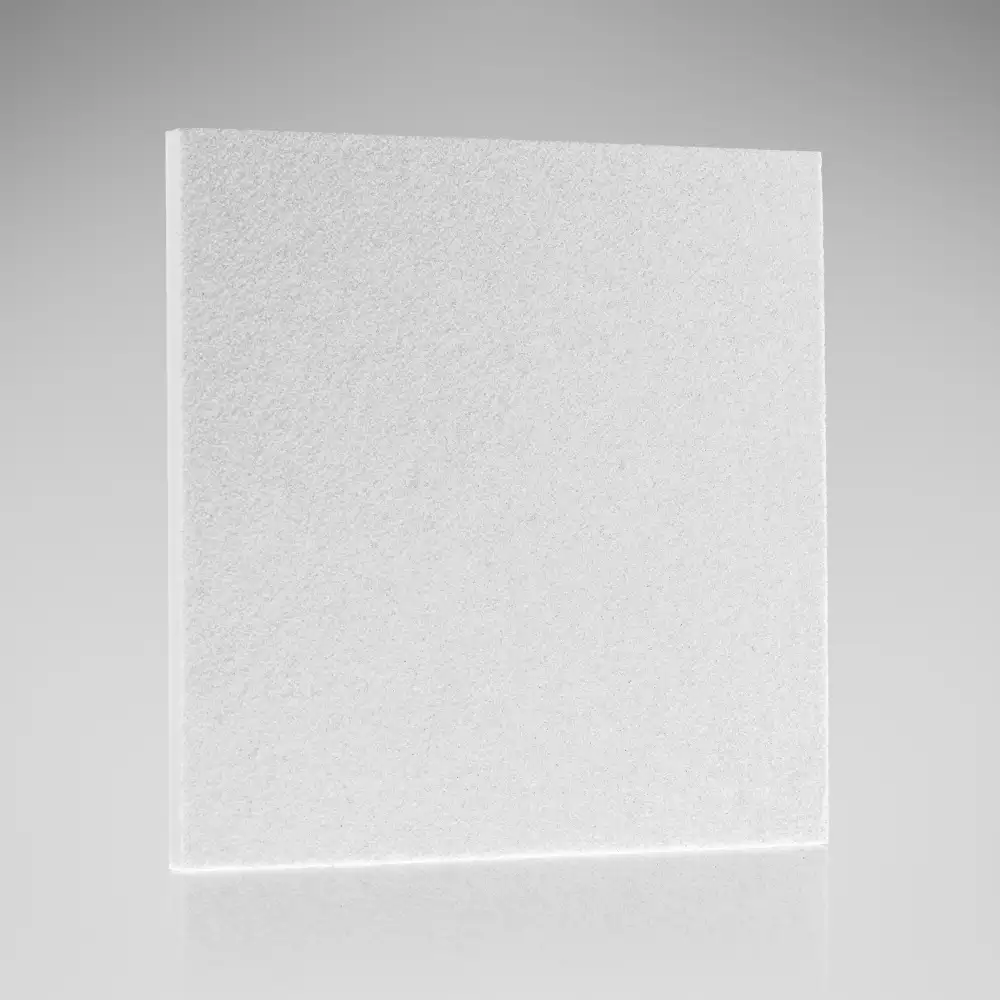

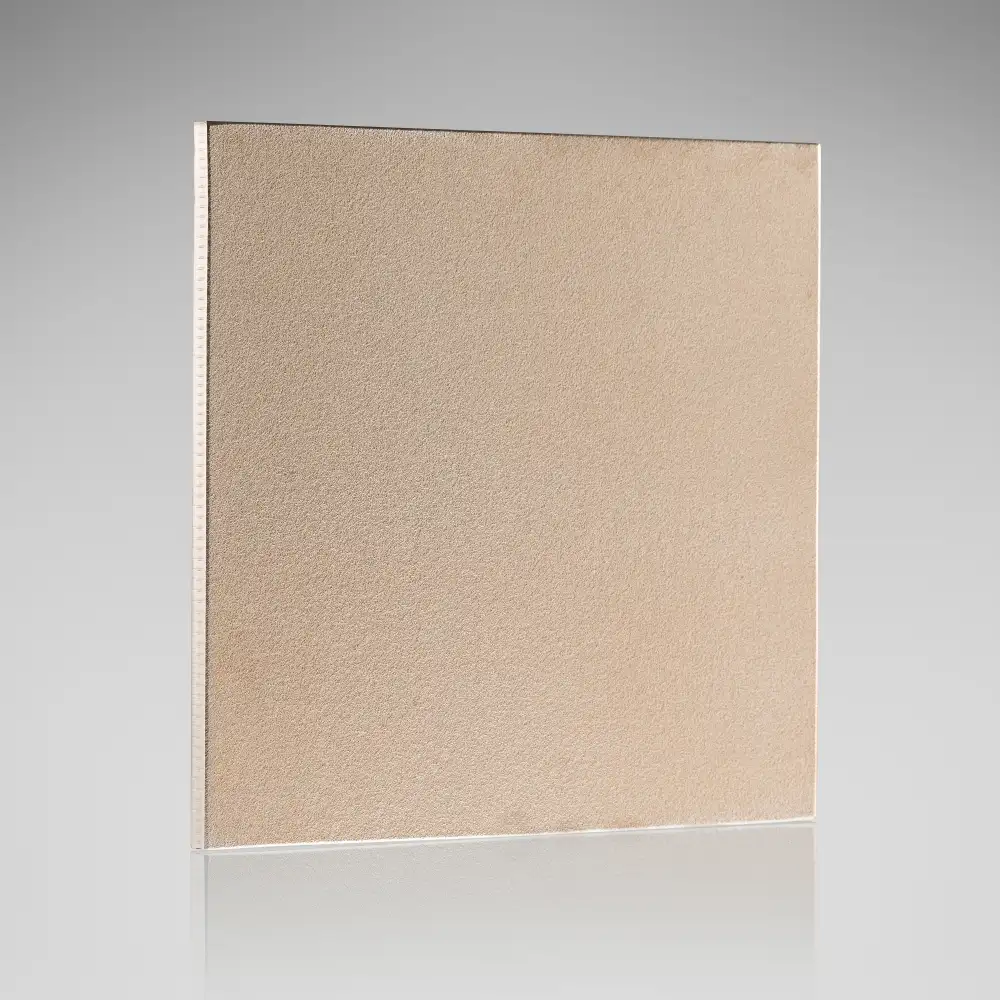

Plates and circular blanks

SIPERM® sheets and discs

are manufactured in various standard formats. Dimensions and material thicknesses vary between material groups, as different sintering processes and mechanical properties enable different geometries. Stainless steel plates typically reach sizes of 250 × 250 mm or 280 × 220 mm, bronze plates up to 1000 × 450 mm and polyethylene plates up to 1200 × 1000 mm.

The material thicknesses range between 2 and 20 mm, depending on the material. Lower thicknesses enable low pressure losses and fast reaction times in flow processes. Higher material thicknesses allow higher mechanical loads and often serve as a structural basis for welded constructions. In homogenization or fluidization applications, uniform pore distribution over the entire surface is crucial as it ensures stable gas distribution over large areas.

Circular blanks are used as base bodies for filter elements, ventilation surfaces, protective caps or flow distributors. As many industrial applications have round connection geometries, the wide selection of tool diameters allows flexible adaptation.

During further processing, machining such as drilling or milling should only be carried out where the function of the flow is not impaired. In many systems, the flow through the panel is defined over the entire surface, meaning that changes to the surface could create unwanted flow bottlenecks. Water jet processes are suitable for contoured components, as they do not clog the pores and produce a sharp edge quality.

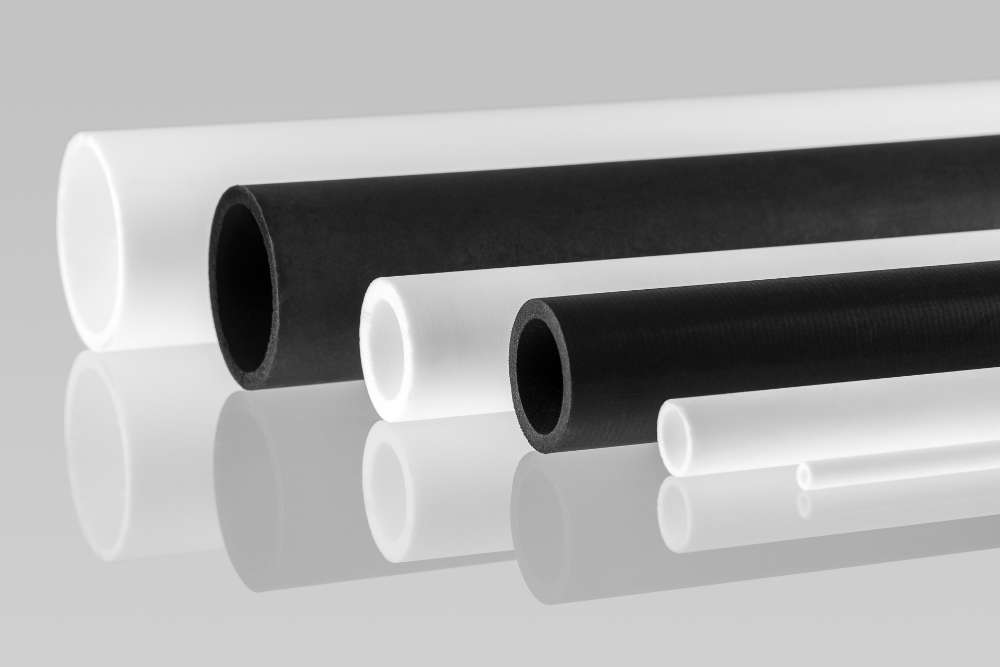

Tubes and candles

Porous SIPERM® tubes and candles

are required for applications in which flow is to take place radially through the pipe wall. The flow behavior differs fundamentally from axial flow, as the pressure distribution over the entire circumferential surface must be taken into account. Pipes made of SIPERM® R are often manufactured seamlessly, which increases roundness and pressure stability. The outer diameter of seamless stainless steel pipes is usually up to 100 mm, the lengths up to around 1000 mm.

Welded constructions allow for larger geometries or additional connection variants such as flanges or threaded rings. When welding, it is important to maintain a high welding speed, as otherwise the porous structure can compact at the seam. Polyethylene pipes are lighter and are mainly used where chemical resistance or low weight is more important than maximum pressure resistance.

Bronze and stainless steel pipes are often used as filter cartridges. The radially directed flow leads to defined pressure loss profiles that can be calculated according to Darcy or extended fluid mechanical model approaches. The combination of porous shell surface and mechanical stability also enables applications such as suction and compaction processes in bulk solids technology.

Filter cartridges made of SIPERM® R, B or HP are used to separate particles from gases or liquids. The pore sizes are between 1 and 200 µm. Stainless steel filters are preferred when high temperatures, aggressive cleaning processes or high mechanical loads occur. Bronze offers low pressure losses, polyethylene chemical resistance and low weight.

Filter cartridges are used to separate solid particles, stabilize gas flows or separate ultra-fine particles. The filter efficiency is increased if depth filter effects dominate, which is the case in porous sintered materials due to the branched channel structure. For aggressive media, backwashing processes can be used to flush the pore network free again.

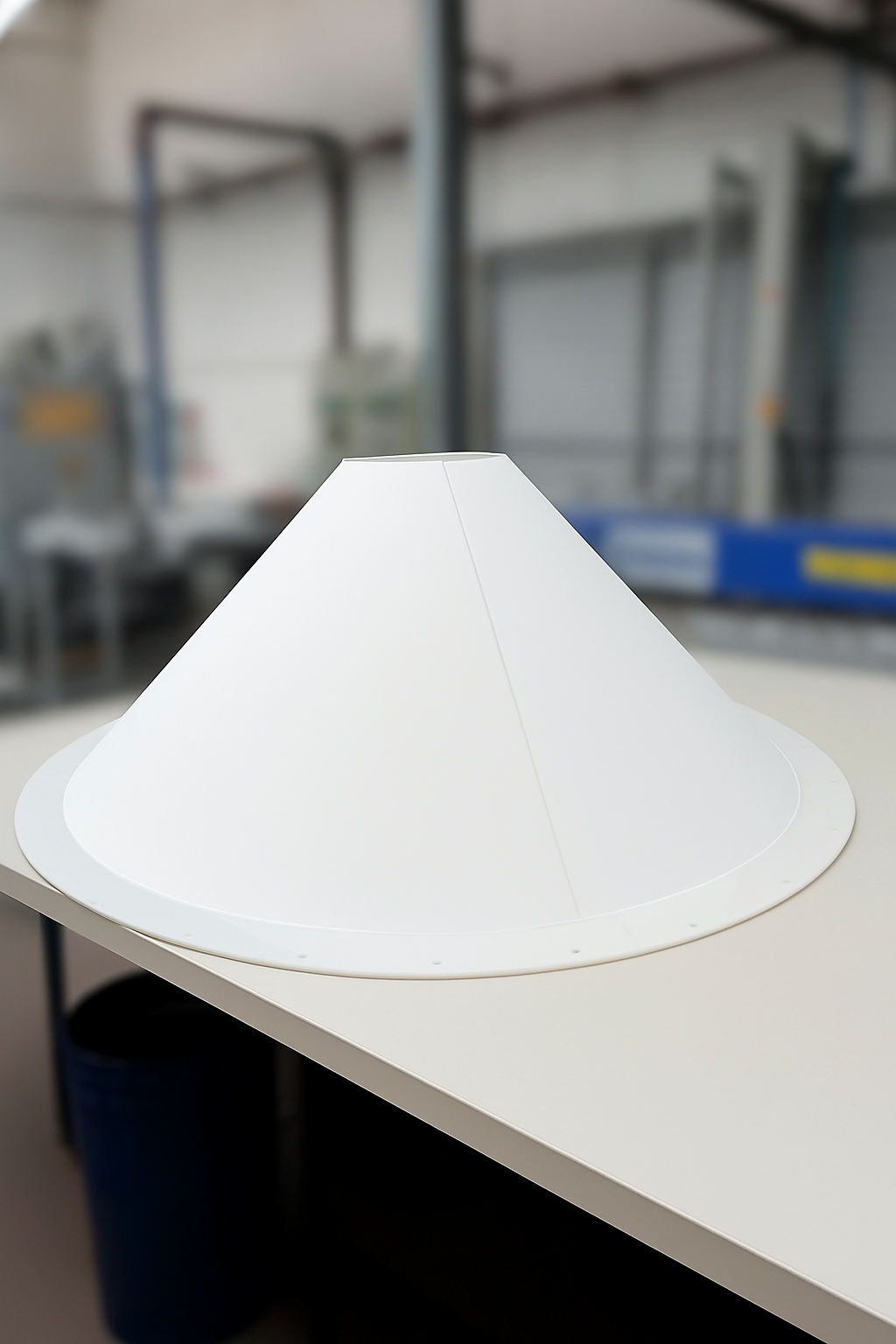

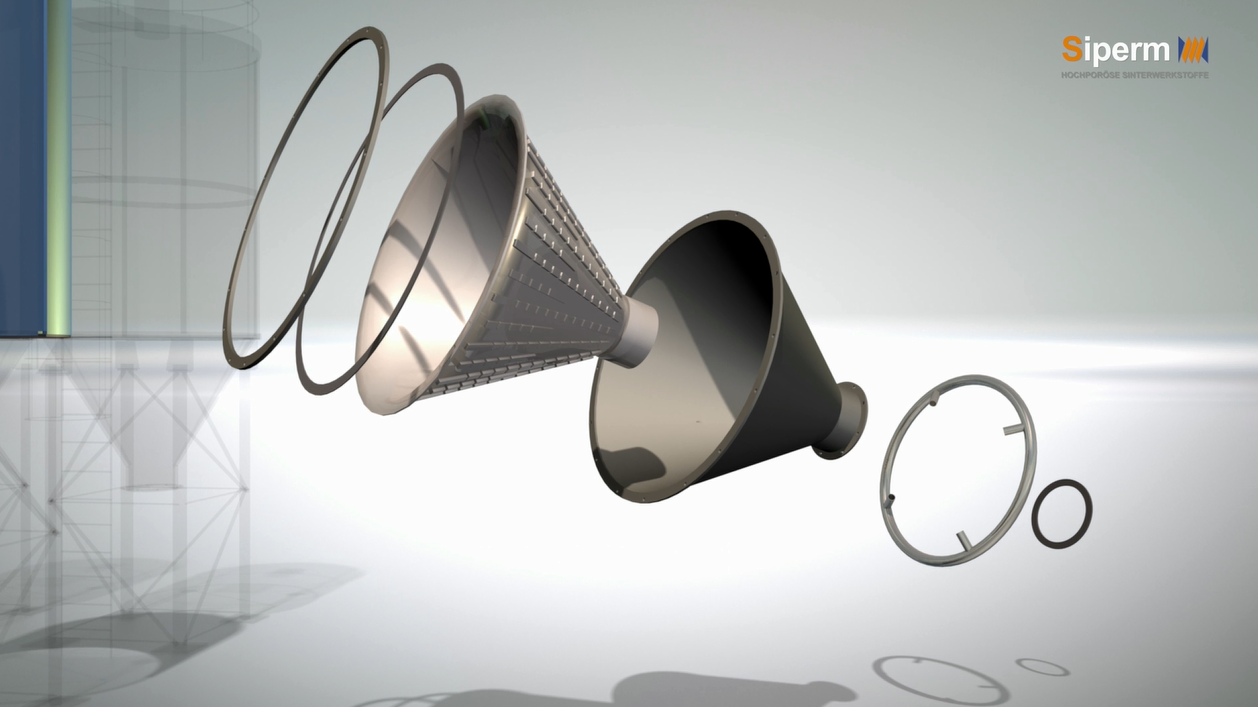

Molded parts

Molded parts made from SIPERM®

are used for applications that require geometrically adapted porous components with defined flow, filter or damping properties. The porous structure remains open and functional over the entire component thickness, provided that no local compaction occurs during processing. By pressing in tools (SIPERM® R) or by pouring the powder material into molds (SIPERM® B, SIPERM® HP), reproducible geometries are created that can be integrated into technical systems.

The properties result from the combination of material, pore size and wall thickness. SIPERM® R enables mechanically stable and temperature-resistant molded parts, for example for filter cartridges, connection elements or sensor protection components with an additional flame-retardant effect. SIPERM® B offers low pressure losses and a homogeneous pore structure, allowing moulded parts to be used for gas distribution, venting or as flow-optimized inserts in pneumatic systems. SIPERM® HP is used for lightweight, chemically resistant molded parts, such as protective caps, flow calmers or ventilation elements in measuring and analysis devices.

Typical areas of application include filtration, sensor protection, sound attenuation, gas distribution and ventilation. The molded parts enable uniform flow profiles, particle retention, defined flow rates and the mechanical protection of sensitive components. This provides compact, function-oriented components that can be used reliably in various industrial processes.

Fluidization units and ventilation elements

Fluidization and ventilation elements made of SIPERM

are used in bulk solids technology. Here, process air is introduced evenly into the bulk material via a porous surface. The homogeneous gas distribution is created by the continuous porous structure of the materials and ensures that frictional and cohesive forces in the material are reduced. This prevents bridging, shaft formation and uneven discharge.

Large-area aeration floors, which can consist of several SIPERM® segments, are used for large system areas. The arrangement of the segments enables uniform loading of larger container surfaces and adaptation to rectangular, conical or asymmetrical container geometries. These surfaces serve as a permeable zone for the process air and stabilize the material flow across the entire width of the container.

For smaller applications, punctual ventilation elements are available, such as round or rectangular inserts, which are used locally where additional support is required. These include ventilation spots, pads and compact fluidizing elements. They are integrated directly into container and hopper walls or retrofitted into existing systems and are used for targeted relief of individual areas.

In systems where defined flow paths, special connection geometries or increased mechanical stability are required, welded constructions made of SIPERM® R are used. Here, porous SIPERM® R sheets or pipes are connected to solid connecting or retaining elements, with welding only taking place outside the porous functional surface. As a result, the permeability of the active areas is completely retained. Welded constructions enable large-format functional surfaces, porous pipe sections in complex pipe systems or combined components with defined connection points.

In this way, large aeration areas as well as compact fluidization units and application-specific assemblies can be realized in different material variants. The choice of SIPERM® material depends on the temperature range, chemical load, flow requirements and mechanical stress during operation.

Products made from porous SIPERM® materials

The SIPERM® product line comprises three porous sintered materials: SIPERM® R (stainless steel 1.4404), SIPERM® B (bronze CuSn10) and SIPERM® HP (polyethylene PE-UHMW/HDPE). These materials are produced from defined grain fractions that are compacted and then sintered. During sintering, the particles combine to form a solid structure in which continuous pore channels are created. The size of these pore channels is determined by the particle size distribution of the starting material used. This results in reproducible porosities, defined pressure losses and mechanical characteristics that are tested in accordance with DIN ISO 4022 and DIN ISO 4003. All values stated here are average values and may vary depending on dimensions and wall thicknesses, as described in the technical data sheets.

The three materials differ significantly in terms of their functional properties. SIPERM® R offers high chemical resistance and is temperature-resistant in both oxidizing and reducing atmospheres. SIPERM® B has a very homogeneous pore structure, which is favored by the particle shape used and enables low pressure losses in the application. SIPERM® HP has a high chemical resistance and a hydrophobic surface that can be subsequently made hydrophilic. These material-specific properties determine the suitability for applications in which pressure loss, temperature resistance, chemical stability or defined flow distribution are relevant.

The materials are manufactured as sheets, tubes, circular blanks and molded parts. They can also be further processed into functional components, e.g. by welding. These include filter cartridges, ventilation elements, extraction pipes and ventilation floors. The porous structure enables functions that cannot be realized with solid materials, including the defined flow of gases or liquids, the uniform distribution of process gases, the retention of particles, energy conversion in safety applications and the protection of sensitive measuring and sensor components. The performance of these components results from the specific combination of material, pore size, wall thickness and component geometry.

Post-processing and modification

- The properties of the materials can be further influenced by targeted post-processing:

- Mechanical sealing of pores at desired locations

- Preservation of open-pored surfaces by wire erosion or water jet cutting

- Hydrophilic adjustment of SIPERM® HP by post-treatment

- Electrical conductivity of SIPERM® HP due to additives in the starting powder

Food suitability

The materials SIPERM® R, SIPERM® HP and SIPERM® HP antistatic are food-safe. SIPERM® HP and SIPERM® HP antistatic have a declaration of conformity in accordance with the Foodstuffs Ordinance.

Advantages over product alternatives

Wire mesh

Wire mesh has a mesh-based structure whose flow behavior is highly dependent on the orientation and tolerance of the meshes. This leads to uneven flow and localized turbulence peaks, especially at intersections of the wires. Meshes can deform under mechanical load or vibration, which further impairs the filter or flow performance.

SIPERM® offers a consistently homogeneous pore structure that ensures uniform gas distribution regardless of the direction of flow. The pore sizes are defined and reproducible, and the structure remains stable even under pressure.

Disadvantage: Direction-dependent flow, machine tolerances

SIPERM® advantage: homogeneous pore structure → uniform gas distribution

________________________________________

Metal fleece / metal fiber structures

Metal fleece has a fiber-based deep structure whose pores are created by random fiber layers. As a result, the pore sizes are not reproducible and the structure compresses under pressure or vibration, which significantly changes the permeability and flow performance during operation. There is also the possibility of fiber detachment, which is critical in sensitive applications.

SIPERM®, on the other hand, consists of a dimensionally stable sintered body which, depending on the material, does not compress under medium or high loads. The pores remain constant, the flow remains stable and there are no loose fibers.

Disadvantage: susceptible to compression, pores not defined

SIPERM® advantage: Dimensionally stable pores → constant permeability, no fiber detachment

________________________________________

Plastic fleece

Plastic nonwovens have a random pore distribution and are highly susceptible to compression. The pores and thus the flow characteristics change under pressure, temperature or humidity. The gas distribution is usually uneven due to the inhomogeneous fiber layers.

SIPERM® materials offer a defined pore structure with high dimensional and pressure stability, so that neither pore sizes nor flow resistance change under load. They enable uniform gas distribution and constant function over the entire service life.

Disadvantage: limited temperature and pressure resistance, pores unstable

SIPERM® advantage: stable pores, defined structures, permanent flow through

________________________________________

Porous ceramics

Ceramic filters are temperature-stable but brittle. They react sensitively to vibrations, impact loads or thermal stresses and are prone to material breakage under such stresses. In addition, their geometry, machinability and customization options are limited.

SIPERM® materials are metallic or polymer-based and significantly more resistant to mechanical stress. They do not break brittle, can be cut, machined and welded and integrated into complex assemblies.

Disadvantage: brittle, susceptible to shock and vibration

SIPERM® advantage: metallic/tough → no risk of brittle fracture

________________________________________

Sintered glass

Sintered glass has a fine pore structure, but is mechanically less resilient. It is susceptible to breakage from pressure surges, shock and vibration and can only be integrated into robust assemblies to a limited extent.

SIPERM® offers significantly higher mechanical stability, can absorb pressure loads and vibrations and remains dimensionally stable. Integration into metallic components or brackets is possible without any problems.

Disadvantage: low mechanical stability

SIPERM® advantage: robust against pressure surges, vibration-resistant

________________________________________

Perforated sheets

Perforated plates only have individual openings and no real porosity. The flow is concentrated at these points, resulting in turbulence, local acceleration and uneven gas distribution. Very fine particles cannot be retained and there is no depth effect at all.

SIPERM® offers a continuous, fine-pored functional surface that distributes the flow evenly and at the same time provides a filtration effect. Turbulence is minimized and the entire surface is uniformly permeable.

Disadvantage: punctual openings → no homogeneous flow

SIPERM® advantage: continuous pore surface → uniform gas distribution

FAQ – Products made from porous SIPERM® materials

What is the difference between SIPERM® R, SIPERM® B and SIPERM® HP?

The three material groups cover different areas of application. Stainless steel (SIPERM® R) is used when high temperature resistance, mechanical strength and chemical resistance are required. Bronze (SIPERM® B) is characterized by low pressure losses and a homogeneous pore structure. Polyethylene (SIPERM® HP) offers high chemical resistance, low density and can be adjusted to be both hydrophobic and hydrophilic.

Which geometries are available as standard?

Plates, pipes, circular blanks and molded parts are part of the basic range. The dimensions vary depending on the material: stainless steel sheets, for example, up to 280 × 220 mm, bronze sheets up to 1000 × 500 mm, polyethylene sheets up to 1200 × 1000 mm. Seamless pipes are available up to Ø 100 mm and up to 1000 mm in length, depending on the material.

Information on other standards on request.

Which applications are covered by SIPERM® products?

Typical functional fields are filtration of gases and liquids, bulk material handling (fluidization, aeration, discharge), venting/extraction, sound attenuation, sensor protection, capillary transport and safety applications such as flame arresters.

How is the appropriate degree of porosity selected?

The degree of porosity is selected according to the volume flow, permissible pressure loss, particle sizes or filtration task as well as the thermal and chemical requirements.

We will be happy to work with you to select the perfect material.

Are customized geometries possible?

Yes, porous sheets, pipes and components can be milled, turned, drilled and produced as welded constructions or molded parts. Stainless steel and bronze are TIG-welded, polyethylene by hot gas or heating element process. Molded parts and complex components are manufactured according to drawings.

What temperature ranges do the materials support?

SIPERM® R: up to 500 °C (oxidizing) or 650 °C (reducing).

SIPERM® B: up to 200 °C or 350 °C.

SIPERM® HP: up to approx. 70 °C.

Depending on the application, the application temperature influences the mechanical strength and the permissible load

Differences between the fluidization products

What is the difference between fluidizing elements, aeration trays and aeration cushions?

All fluidization products distribute process gas evenly in bulk materials to improve their flowability.

Ventilation inserts/floors are used in silos and hoppers over large areas and can be manufactured to customer specifications.

Aeration pads and spots are more compact, can also be retrofitted and are suitable for limited zones or areas that are difficult to access.

They reduce friction and cohesion in the bulk material and prevent bridging and shaft formation.

Contact

We are happy to advise you – simply contact us by phone, via email or by using our contact form.

Service

Tridelta Siperm GmbH

Ostkirchstr. 177

44287 Dortmund, Germany