Custom solutions for demanding applications

Siperm®R

Our Address

Tridelta Siperm GmbH

Ostkirchstr. 177

44287 Dortmund, Germany

Stainless steel 1.4404 / AISI 316L

Temperature resistance

500°C oxidizing atmosphere

650°C reducing atmosphere

For more information and technical data, please refer to the PDFs available above

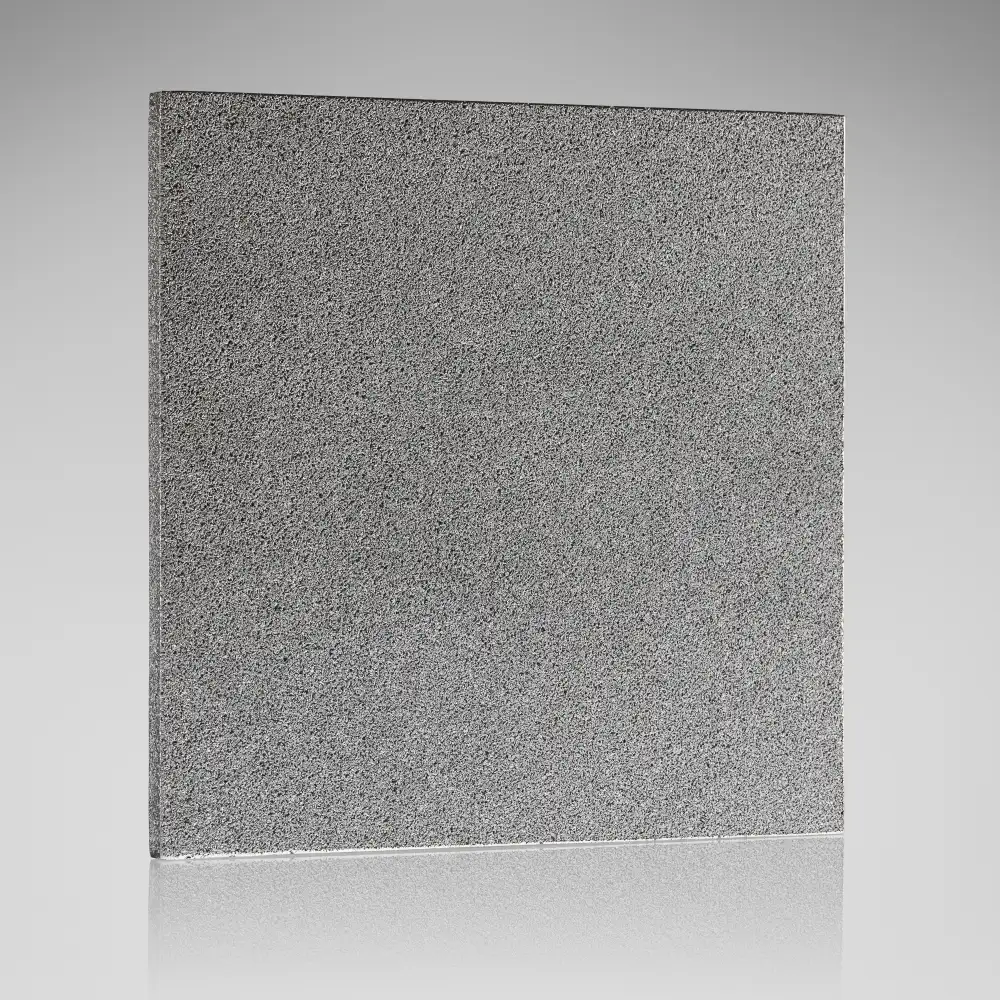

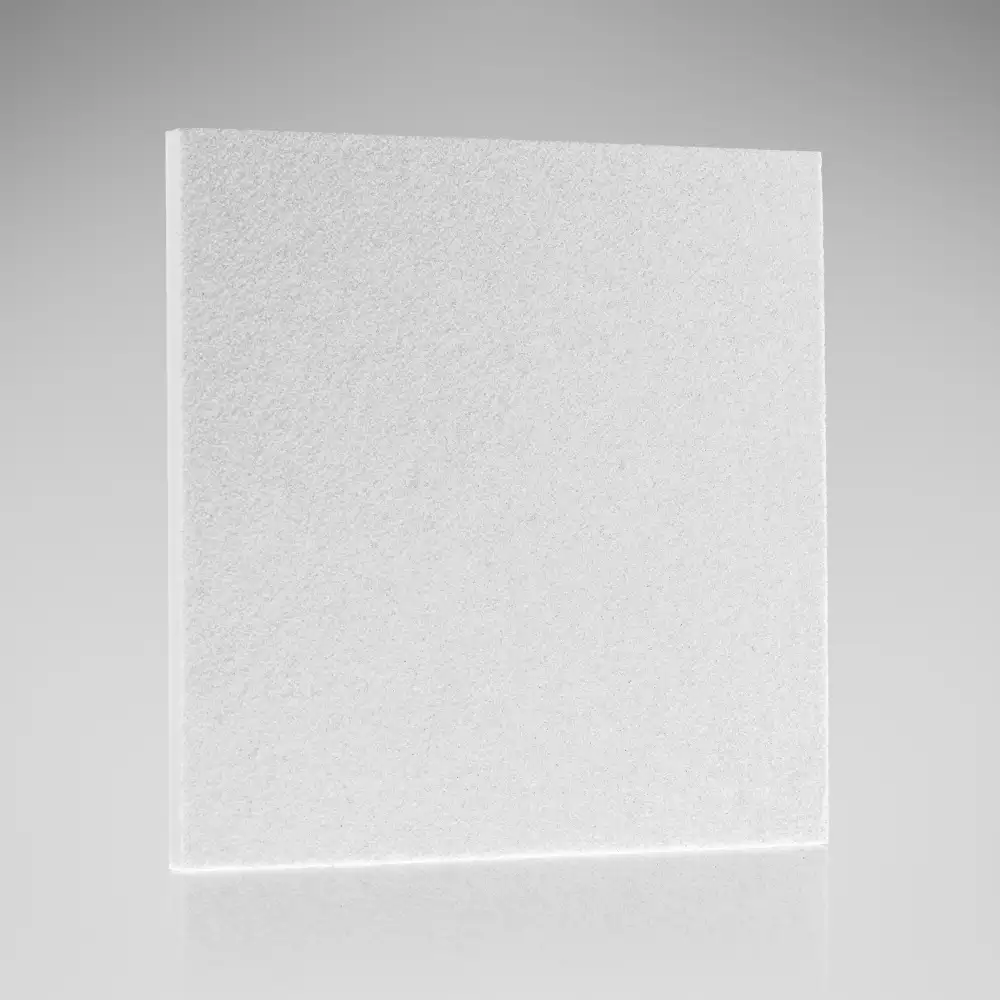

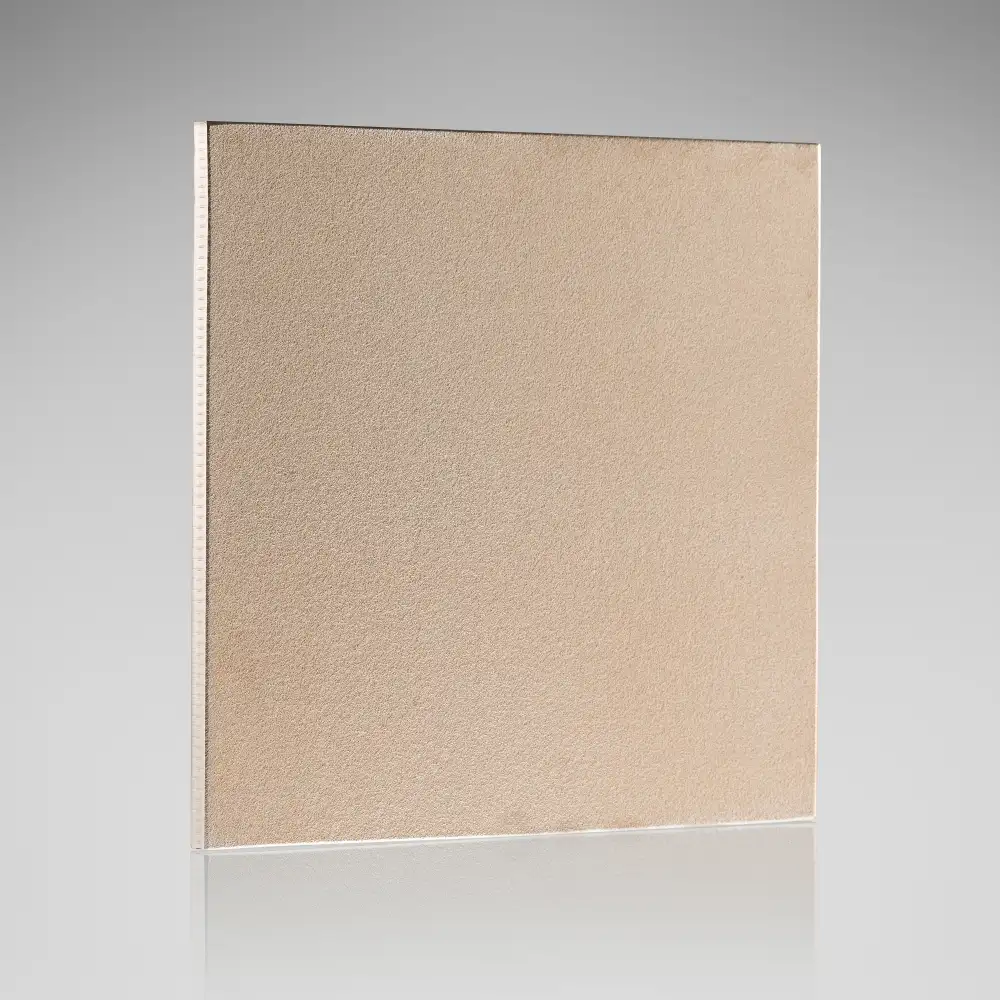

Plates

Size: 280 x 220 mm and 250 x 250 mm, seamless

Thickness: 2 - 10 mm

Other formats (welded constructions and blanks) on request

SIPERM® R plates are made of porous sintered stainless steel 1.4404 and form the basis for numerous functional components in filtration, gas distribution, fluidization and safety technology. The plates are manufactured seamlessly and have a homogeneous distribution of pores over the entire surface, making the flow and filtration properties reproducible.

The defined porosity and mechanical stability of the stainless steel allow it to be used even under thermally demanding conditions of up to 500 °C in an oxidizing atmosphere and up to 650 °C in a reducing atmosphere. Due to the robust microstructure, the sheets can be further processed mechanically - for example by rolling, bending, pressing or embossing. Machinability depends on the degree of porosity: fine grades enable more precise machining, while coarser grades provide higher flow rates. Machining should only be carried out on areas where there is no flow in order to avoid pore blockages.

Typical applications for SIPERM® R sheets range from ventilation panels in silos and filter panels in thermally stressed processes to separating elements, flow stabilizers and functional surfaces in compression systems. Sheets can be welded together to form larger units and can also be adapted to curved geometries using customized bending radii.

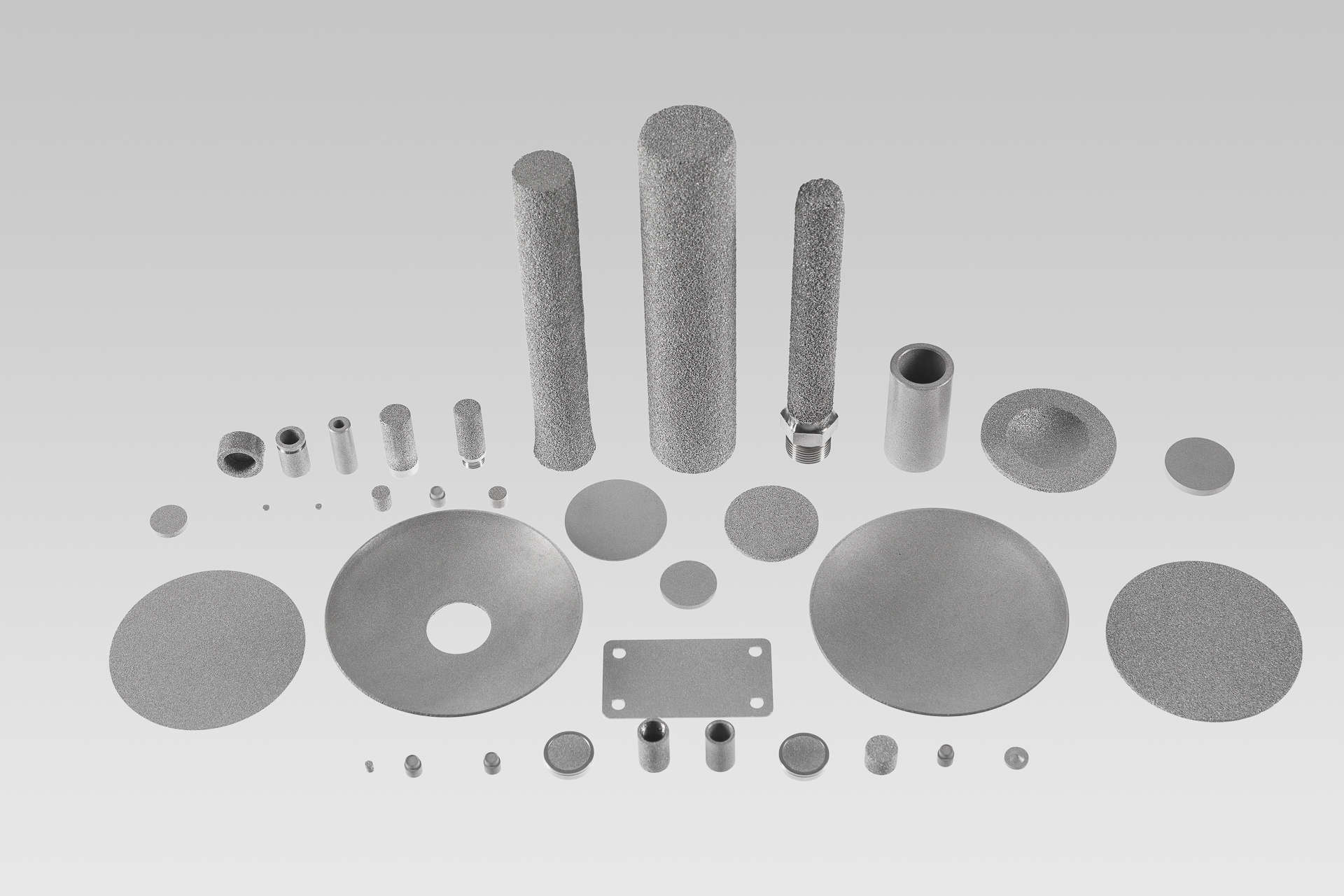

Tubes

seamless and as welded construction - dimensions on request

max. diameter for seamless tubes: 100 mm

max. length for seamless tubes: 1000 mm

Tubes made of SIPERM® R are available as seamless sintered tubes or as welded constructions. Due to their porous structure, these components are particularly suitable for filtration tasks, gas distribution within closed systems and for suction processes in bulk material and powder handling systems.

The uniform pore structure allows a defined radial or axial flow. At the same time, the pipes have a remarkably high burst pressure resistance, the values of which are documented in the technical data sheet. This strength is particularly important for use as filter cartridges, suction lines or pressure relief elements, as high pressure differences sometimes occur here. Stainless steel sintered pipes withstand mechanical and thermal loads without losing their functionality or structural integrity.

Seamless tubes are suitable for applications that require high process reliability, such as gas filtration, air extraction from powder bags or volume reduction in extraction processes. Welded constructions also enable longer component lengths or complex pipe runs if the installation space requires it. The connection to solid stainless steel components is usually made using TIG welding, whereby the aim is to apply as little heat as possible so as not to affect the pore structure.

Circular blanks and molded parts

We have a large range of tools available for the production of circular blanks and molded parts of various sizes. We will be happy to inform you about available dimensions and special shapes on request.

An extensive range of tools is available for circular blanks and individual moulded parts so that round, rectangular or complex-shaped geometries can be realized. The components are produced using defined pressing tools and then sintered, resulting in uniform porosity across the entire cross-section.

Molded parts made of SIPERM® R perform key functions in areas where standard geometries are not sufficient. These include sensor protection bodies, flame arresters, defined flow units, filter segments or fluidization inserts in special geometries. The components can also be combined with solid stainless steel components by welding, riveting or thermal joining to produce hybrid assemblies with integrated connection or housing parts.

A key advantage of SIPERM® R molded parts is that the porous structure is maintained without any loss of function, even in three-dimensional geometries. This enables flow-relevant components with defined wall thicknesses and pore sizes whose properties reliably correspond to the characteristic values specified in the technical data sheet.

Fluidizing units

Aeration spot: Ø80 mm, Ø100 mm, Ø105 mm

Aeration pads: 250 x 125 mm, 500 x 125 mm, 1000 x 125 mm and according to customer specifications

Fluidization trays according to customer requirements

Fluidization units made of SIPERM® R - such as aeration spots, aeration pads and customised fluidization trays - enable the reliable loosening of fine bulk solids in the 10-200 µm range. The defined gas flow reduces the friction between the particles, making the bulk solids almost free-flowing. This prevents bridging, shaft formation and segregation effects in silos, hoppers and discharge systems.

Standard components such as spots and cushions are ready-to-use modules made of porous stainless steel with solid connection components. They can be installed in new or existing systems and do not require regular maintenance. For large-scale applications, customized fluidizing floors can be designed that can be divided into segments to control the gas supply section by section.

The decisive factor is that the medium supplied - typically air or nitrogen - must be dry and free of oil or particles. The pressure loss depends on the porosity, the material thickness and the dimensioning of the fluidization surface. The homogeneous pore structure of SIPERM® R ensures uniform gas distribution, so that systems can be operated with comparatively low air volumes.

The robust stainless steel structure allows use at high temperatures or in chemically demanding environments. The components are easy to clean, can be cleaned dry or wet and have a long service life.

Filter cartridges

seamless and as welded construction - dimensions on request

max. diameter for seamless tubes: 100 mm

max. length for seamless tubes: 1000 mm

Filter cartridges made of SIPERM® R are manufactured as seamless sintered tubes or as welded constructions and are suitable for demanding filtration tasks in gases and liquids. Depending on the quality, the pore sizes range from 1 to 200 µm, making both fine filtration and pre-separation possible.

SIPERM® R filter cartridges are temperature-stable, pressure-resistant and chemically resistant. They can be used in processes where high thermal and mechanical loads occur, e.g. in chemical reaction systems, thermal gas flows or in the filtration of viscous plastic melts. The structurally homogeneous pore distribution leads to reproducible separation efficiencies and stable pressure loss characteristics.

A major advantage is the cleanability of the filter elements. Backwashing, superheated steam treatment, ultrasound or chemical cleaning are possible, provided the medium used is compatible. The increased internal surface area of porous sintered materials enables high filtration efficiency, but requires compliance with the recommended cleaning times and temperatures.

Filter cartridges can be combined with solid stainless steel connections to be integrated directly into existing filter housings. Threads, flanges or adapters are either welded on or produced in a combined pressing/sintering process to create tight and durable connections.

SIPERM® R

Material basis and positioning

SIPERM® R is a porous sintered material made of stainless steel 1.4404 (AISI 316L) that has been developed for industrial applications in which defined flow, pressure or filter properties must be maintained under demanding conditions. The material is produced by sintering stainless steel powders, which are processed in controlled grain fractions and press densities. During the thermal process, the metal particles bond together permanently, creating a stable structure in which an open pore network is formed.

The structure differs fundamentally from wire mesh, perforated sheets or polymeric filter materials. While these materials form flow paths via individual openings or fibers, SIPERM® R creates a three-dimensionally cross-linked pore space that is uniform across the entire wall thickness. The porosity is not a side effect of production, but a specifically set material parameter. The resulting characteristic values – pore size, permeability, pressure loss – are reproducible and determined in accordance with standards.

SIPERM® R is used wherever materials are required that are simultaneously porous, mechanically stable and thermally resilient. Typical areas of application range from process, measurement and safety technology to flow-guiding functional surfaces. The central role of the material is to guide, dampen or distribute flows – under conditions where conventional filter media would fail.

Microstructure and characteristics of the pore network

The characteristic feature of SIPERM® R is the continuous pore structure. The pores are created when the individual particles fuse at their contact points during the sintering process, while the spaces in between remain as a defined cavity structure.

Distribution and size of the pores

Depending on the selected material quality, the pore sizes range from around 1 to 200 µm. The exact distribution is defined by the grain size used and the press density. The test methods follow DIN ISO 4022 for permeability and DIN ISO 4003 for bubble point measurements.

These parameters make it possible to calculate flow paths, pressure losses and retention levels in advance. The homogeneity across the material surface prevents local constrictions or “hotspots”, which can occur with woven structures.

Open porosity as a functional principle

The structure allows a uniform flow in any direction, provided the component geometry permits this. The open structure fulfills several functions simultaneously:

- Transportation and distribution of the medium

- Controlled pressure reduction

- Flow calming

- Defined particle retention

- Energy conversion through friction in the duct structure

This multifunctionality is a key unique selling point of porous sintered materials compared to one-dimensional or two-dimensional filter systems.

Flow behavior of SIPERM® R

The flow characteristics of SIPERM® R are made up of laminar-dominated and turbulent components. The specific coefficients are material-specific and are available separately for each porosity quality. This means that the flow behavior can not only be observed empirically, but can also be planned technically.

Laminar flow

At low flow velocities, the movement of the medium is predominantly laminar. The pressure loss increases proportionally to the volume flow, which enables precise prediction. This property is important for applications where a stable flow profile is required.

Turbulent flow

As the flow rate increases, the turbulent proportion in the pore system grows. As the flow in the branched channels is repeatedly accelerated, decelerated and deflected, the pressure loss in this area increases disproportionately. This effect is already taken into account in the material characteristic value and can be used for technical calculations.

Flow stabilization as a material function

Thanks to the network of microchannels, SIPERM® R acts as a natural flow damper. Local pressure peaks are reduced, the speed of the medium is homogenized and uneven flow fields are smoothed out. This is precisely one of the key advantages of the material: it enables reproducible process conditions, even if external factors fluctuate.

Mechanical properties and strength behavior

Despite its porosity, SIPERM® R is characterized by high mechanical stability. The metallic bonds that are formed during sintering create a load-bearing structure in which the strength is not only derived from the material matrix itself, but also from the large number of contact points between the stainless steel particles. The strength characteristics – including tensile strength, bending strength and shear strength – are documented for each specific material and form the basis for the structural design.

Mechanical stability is particularly relevant when components are used under differential pressure or mechanical loads. SIPERM® R is used in applications where pressure differences occur that would overtax conventional porous materials. The robustness of the material also allows it to be used in oscillation and vibration environments without the pore structure collapsing or changing significantly.

The strength depends on the degree of porosity: finer grades have a higher material density and therefore higher strength values, while coarser grades offer higher permeability but have lower mechanical properties. This correlation is essential for design decisions and must be taken into account for wall thicknesses, surface design and pressure loads.

Thermal behavior and temperature resistance

The base material stainless steel 1.4404 gives SIPERM® R high temperature stability. The material can be used reliably in oxidizing atmospheres up to 500 °C and in reducing atmospheres up to 650 °C without affecting the microstructure or function.

In this temperature range, the pore structure remains completely intact. Unlike polymer-based filters or fibrous structures, the sintered metal structure does not undergo thermal softening or structural shrinkage. This represents a significant technical advantage, as many applications – such as process gas routing, venting or flow control – operate under high thermal loads.

Even rapid temperature changes do not cause the structure to fail. Due to the homogeneous metal matrix and uniform pore distribution, no local stresses occur that could jeopardize the mechanical integrity. This makes SIPERM® R suitable for thermally cyclical processes.

Chemical resistance and media compatibility

The material inherits the chemical resistance of stainless steel 1.4404. This means that SIPERM® R remains stable in numerous industrial media, including:

- Many solvents

- Process gases

- organic substances

- Weak acids and bases

However, the large inner surface of the material leads to a stronger interaction with media than with solid stainless steel. This means that cleaning conditions and exposure times must be controlled particularly precisely.

In the case of chemically aggressive media or high concentrations, the design must be carried out with appropriate care. Under typical industrial process conditions, however, SIPERM® R offers stable and permanent chemical resistance.

Processing properties and structural integration

Despite its porosity, SIPERM® R is a machinable metallic material. Machinability depends on the porosity selected, as finer grades offer more material contact and more stable cutting conditions.

Mechanical processing

- Rolling, bending, pressing and embossing are possible.

- Machining may only be carried out on areas where there is no air flow, so as not to close pores.

- Water jet cutting and spark erosion are the preferred processes for contour-accurate cuts.

Connection technology

SIPERM® R can be joined to solid stainless steel parts using TIG welding. A low heat input is important in order to avoid local compaction of the pore space.

These joining techniques enable functional components in which porous and solid zones are combined – such as flow surfaces, sensor connections or components for pressure areas.

Cleaning and maintaining functionality

The porous structure of SIPERM® R has a large internal surface area, which is crucial for its functionality, but can also lead to deposits within the pores. Cleanability is therefore a key aspect for long-term operation. The material can be reliably cleaned using several methods, provided these are correctly matched to the medium and the degree of contamination.

Mechanical cleaning

Mechanical counterflow cleaning is the preferred method for surface or loosely bound particles. A suitable gas or liquid is passed through the component in the opposite direction to the operating flow in order to remove deposits. This can often be carried out without removing the component and is suitable for regular maintenance intervals.

Thermal or physical cleaning

Superheated steam treatment and – if the component can be removed – ultrasonic cleaning loosen particles that have settled deeper in the pore system. The physical processes do not affect the material structure, but require a controlled procedure in order to avoid thermal overloads or incomplete drying.

Dry cleaning

Chemical cleaning agents such as alcohols, acetone or diluted acids can be used if inorganic or organic residues adhere more strongly. Due to the high internal surface area, however, it is necessary to precisely limit the exposure time. After each chemical cleaning, complete rinsing and drying is essential to ensure that no residues remain in the pore system.

The combination of different cleaning processes generally enables complete restoration of permeability. This makes SIPERM® R a material that can be used in the long term and whose functional properties remain stable over many operating cycles.

Functional advantages in an industrial environment

SIPERM® R is used in technical applications where a combination of flow control, mechanical stability and thermal resistance is required. The porous structure offers several functional advantages that cannot be achieved in this form by alternative materials.

Reproducible flow parameters

The clearly defined pore sizes and flow coefficients enable the precise calculation of pressure losses and volume flows. The material behaves reproducibly, even with temperature or load changes.

Homogeneous media routing

The cross-linked pore structure distributes the medium evenly over the entire surface. Flow inhomogeneities are reduced, which stabilizes sensitive processes.

High mechanical and thermal robustness

In contrast to fibrous or polymeric filter materials, SIPERM® R remains dimensionally and functionally stable even at high temperatures. The metal matrix reliably withstands mechanical vibrations, pressure surges and cyclical loads.

Process reliability through defined porosity

The pore size determines the retention behavior, the flow coefficients determine the pressure loss behavior – both variables are defined and measurable. This allows the material to be specifically designed for safety-relevant processes.

Long-term usability

Thanks to its cleanability and structural stability, it retains its functionality for years. The material does not need to be replaced frequently, which offers both technical and economic advantages.

Summary

SIPERM® R is a porous stainless steel material manufactured with technical precision that is characterized by a combination of reproducible porosity, high mechanical stability, thermal resilience and chemical resistance. The continuous pore network enables defined flow and filter properties that behave reliably under all operating conditions.

The mechanical properties allow use in pressurized or dynamic systems, while the temperature resistance enables applications in high-temperature or thermally cyclical processes. The chemical resistance and good cleanability ensure a long service life of the material – a significant advantage over non-metallic filter systems.

The combination of these properties makes SIPERM® R a material that is used as a functional element in many industrial sectors when media with defined parameters need to be guided, calmed, distributed or retained. The technical characteristics enable precise design and the versatility of the material allows it to be integrated into a wide range of system concepts and process environments.

Contact

We are happy to advise you – simply contact us by phone, via email or by using our contact form.

Service

Tridelta Siperm GmbH

Ostkirchstr. 177

44287 Dortmund, Germany